Plastic injection molding in the USA has transformed manufacturing practices across various industries. As noted in a 2022 report by the American Plastics Manufacturing Association, this technique offers significant cost savings and efficiency. Industry expert, Dr. Emily Carter, emphasizes, "In today’s fast-paced market, plastic injection molding holds the key to staying competitive."

The advantages of plastic injection molding extend beyond cost-effectiveness. For instance, it enables the creation of complex designs with precision. In sectors like automotive and consumer goods, this method supports rapid production timelines. With increased sustainability initiatives, it's crucial to acknowledge that the process does come with challenges. Not every project achieves the anticipated efficiency, leading to discussions on optimizing practices.

Manufacturers often face obstacles in material selection and design fidelity. A balance must be struck between innovation and practicality. Understanding these dynamics is essential for capitalizing on the benefits of plastic injection molding in the USA. Ultimately, this growing sector must reflect on its practices to enhance both productivity and environmental footprint.

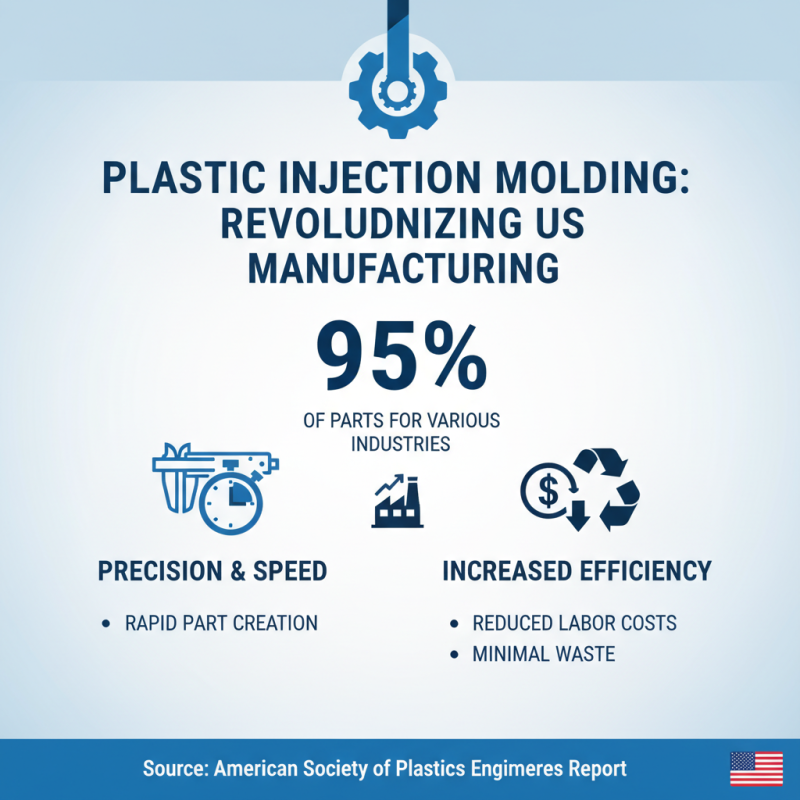

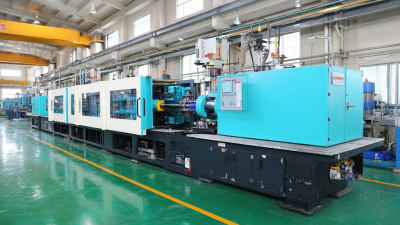

Plastic injection molding is revolutionizing manufacturing efficiency in the USA. This process allows for precision and speed in creating plastic parts. According to a report by the American Society of Plastics Engineers, injection molding can produce up to 95% of the parts needed for various industries. This efficiency translates to reduced labor costs and minimal waste.

The method also supports complex designs that are often hard to achieve with traditional manufacturing methods. Many companies report a reduction in production time by 30% or more. These improvements often lead to quicker market delivery. However, challenges remain. Not every design can be effectively molded. Some prototypes may require multiple adjustments. This creates a need for continual refinement and testing, which can add time and cost.

Moreover, the initial setup requires significant investment. Companies must consider mold design and machinery that can handle specific thermoplastics. Balancing cost with efficiency is key. Nonetheless, the long-term benefits can outweigh these initial hurdles, making plastic injection molding a popular choice.

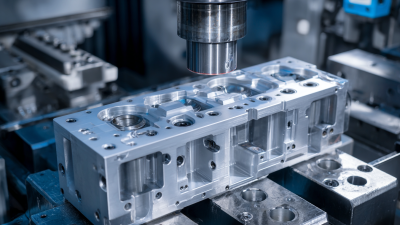

Plastic injection molding is a vital process in manufacturing. It offers unique cost advantages in production. This method reduces waste significantly compared to other techniques. Materials are used efficiently, leading to lower raw material costs. This efficiency can drive down the overall production expenses.

Furthermore, the speed of production is noteworthy. Once molds are created, large quantities can be produced quickly. This fast turnaround can meet urgent market demands. Prototyping can be done effectively, allowing for adjustments before mass production begins. However, the initial investment in designing molds may seem high. This requires careful planning and budgeting.

Another consideration is the versatility of materials used. Different plastics can yield various properties. This flexibility can be both a strength and a challenge. Choosing the right material is crucial for product quality. Overall, while there are clear advantages, potential pitfalls exist in planning and execution. Manufacturers must weigh these factors to achieve the best results.

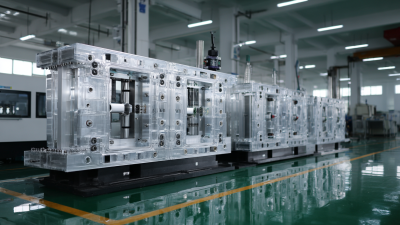

Plastic injection molding offers remarkable design flexibility and customization opportunities. Designers can create complex shapes that are often impossible with other methods. This process allows for intricate details, textures, and features to be incorporated seamlessly. For instance, small components can be molded with precision, ensuring that every part fits perfectly in the final assembly.

However, achieving the desired results requires careful planning and execution. Sometimes, designs must be altered to accommodate manufacturing constraints. This can lead to frustration for designers who envision a different outcome. It's essential to balance creativity with technical feasibility. The tools and molds used can significantly impact the final product, making some designs more challenging to realize.

Additionally, rapid prototyping is another advantage. It enables designers to quickly test and validate their concepts. But not every prototype leads to success. Some might reveal unforeseen issues that necessitate further adjustments. While plastic injection molding is versatile, its effectiveness relies heavily on collaboration between designers and engineers. This relationship can lead to innovative creations, but it requires open communication and willingness to adapt.

Plastic injection molding plays a significant role in the realm of sustainability. It allows for efficient use of materials. This process minimizes waste by utilizing precisely the right amount of plastic needed. However, there are challenges in recycling some types of plastics. Not all materials used in injection molding are recycled easily. This can lead to environmental concerns if not managed properly.

The energy consumption of plastic injection molding is another area that warrants attention. Modern machines are becoming more energy-efficient. Yet, the overall carbon footprint can still be substantial. It's crucial for manufacturers to weigh the benefits against the environmental impact. Investment in renewable energy sources can help mitigate these effects. The industry is shifting towards greener practices, but there's still room for improvement. We must continually assess how this process can evolve for a more sustainable future.

Plastic injection molding plays a vital role in various industries across the USA. It is widely used in automotive manufacturing. According to a report by Grand View Research, the automotive plastics market is projected to reach $37.5 billion by 2025. Parts like dashboards, bumpers, and panels are often produced using this method, increasing production efficiency. This technique allows for complex designs that can enhance vehicle aesthetics and functionality.

Another significant application is in consumer goods. Items such as containers, toys, and electronic housings are commonly made via injection molding. The versatility of materials enables manufacturers to create products that meet specific requirements. However, not all products fit perfectly. Some designs can result in wasted material or require extensive finishing. This aspect of production raises questions about sustainability and efficiency. Reducing scrap is still a challenge in many factories, and ongoing adjustments in the molding process are necessary.

Moreover, the medical industry benefits greatly from plastic injection molding. Devices like syringes and IV bags are produced with high precision. The increased demand for medical supplies has surged, especially during health crises. Yet, maintaining quality standards can be difficult. Variability in material properties may lead to defects. Continuous monitoring and testing are essential to ensure safety and effectiveness. Balancing speed and quality remains a key challenge in this evolving industry.

| Benefit | Description | Applicable Industries |

|---|---|---|

| High Efficiency | Allows for mass production of parts with consistent quality at a rapid pace. | Automotive, Consumer Goods |

| Cost-Effective | Reduces per-unit manufacturing costs with large production runs. | Electronics, Packaging |

| Design Flexibility | Facilitates complex shapes and designs with high precision. | Medical Devices, Aerospace |

| Material Variety | A wide selection of plastics to meet different performance requirements. | Consumer Goods, Automotive |

| Reduced Waste | Minimizes material waste through efficient production methods. | General Manufacturing, Electronics |

| Rapid Prototyping | Enables quick iteration of designs for testing and evaluation. | Product Development, Aerospace |

| Strength and Durability | Produces strong and resilient parts suitable for various applications. | Automotive, Medical Devices |

| Automation Friendly | Easily integrates with automated systems for streamlined operations. | Manufacturing, Electronics |

| Sustainability | Supports recycling and use of eco-friendly materials. | Packaging, Consumer Goods |

880 W 9th Street

Upland, California 91786

884 W 9th Street

Upland, California 91786

886 W 9th Street

Upland, California 91786

884 W 9th Street

Upland, California 91786