In recent years, the global landscape of plastic manufacturing has undergone significant transformations, driven by technological advancements and shifting market demands. As businesses prepare for 2025, understanding and implementing innovative plastic manufacturing techniques will be crucial for staying competitive. These methods not only enhance the quality and efficiency of production but also align with sustainability goals that are increasingly important to consumers and regulatory bodies alike.

The evolution of plastic manufacturing is marked by the integration of new materials, automation, and smart manufacturing processes. Companies that embrace these innovations will not only improve their operational efficiencies but also unlock new opportunities for product development and market expansion.

As we delve into the various innovative techniques on the horizon, it becomes evident that the future of plastic manufacturing holds the key to boosting business success in an ever-evolving market. By focusing on these advancements, businesses can better position themselves to meet the challenges and demands of 2025 and beyond.

In 2025, the landscape of plastic manufacturing is evolving towards sustainability, driven by innovative recycling methods. One promising technique is chemical recycling, which breaks down plastic waste into its fundamental monomers, allowing for the creation of new, high-quality plastics. This method not only reduces landfill waste but also minimizes dependency on virgin resources. Companies adopting this approach can considerably lower their carbon footprint while maintaining product integrity and safety.

Additionally, advances in biodegradable and bio-based plastics are reshaping production processes. By utilizing renewable materials, businesses can offer eco-friendly alternatives that appeal to environmentally-conscious consumers. Innovations such as enzyme-based degradation and compostable packaging solutions will become increasingly important, enabling manufacturers to meet stringent environmental regulations and consumer demands. These sustainable methods not only enhance brand reputation but also foster a circular economy, where plastic is reused and repurposed, ensuring longevity and reduced environmental impact.

Advanced 3D printing techniques are transforming the landscape of plastic manufacturing, offering innovative solutions across various applications. In sectors such as construction, electronics, and aerospace, 3D printing enables the creation of complex geometries that traditional manufacturing methods struggle to achieve. For instance, in the aerospace sector, lightweight plastic components can be crafted with precision, enhancing fuel efficiency and performance while reducing waste.

Tips for integrating advanced 3D printing into your business include investing in training for your workforce to master new technologies and exploring partnerships with specialized service providers. Additionally, consider implementing a robust quality control process to ensure that printed components meet industry standards. This proactive approach can set your business apart in a competitive market and position it for future growth.

As the demand for sustainable practices increases, leveraging 3D printing techniques for recycling materials can help in minimizing environmental impacts. Businesses can explore the production of biodegradable plastics through advanced techniques, aligning with global sustainability goals while catering to eco-conscious consumers. Embracing these innovative practices not only boosts operational efficiency but also opens doors to new market opportunities.

| Technique | Applications | Benefits | Estimated Cost Savings (%) | Environmental Impact |

|---|---|---|---|---|

| Fused Deposition Modeling (FDM) | Prototyping, Automotive Parts | Lower material waste, faster prototyping | 20% - 30% | Reduced plastic waste |

| Selective Laser Sintering (SLS) | Aerospace, Medical Devices | High accuracy, complex geometries | 15% - 25% | Less energy-intensive |

| Stereolithography (SLA) | Jewelry, Dental Models | Smooth finish, high detail | 10% - 20% | Utilizes less material |

| Multi-Jet Fusion (MJF) | Consumer Products, Footwear | Speed, durability | 25% - 35% | Lower carbon footprint |

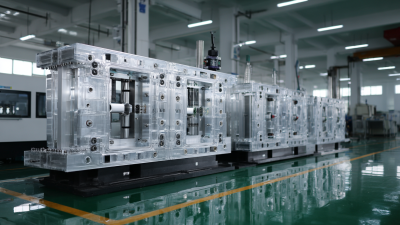

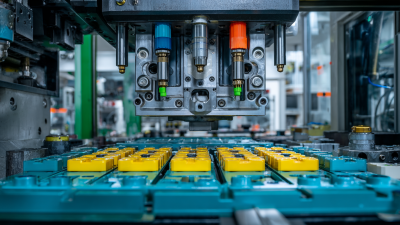

Smart automation in plastic production facilities is transforming the landscape of manufacturing, enabling businesses to enhance efficiency and productivity significantly. By integrating advanced technologies such as robotics, machine learning, and IoT (Internet of Things) solutions, manufacturers can streamline their operations. This leads to reduced labor costs, minimized waste, and improved consistency in product quality. These technologies facilitate real-time monitoring of production processes, allowing for quick adjustments that optimize output while maintaining high standards.

Additionally, smart automation enables predictive maintenance, which is crucial in preventing costly downtime. Sensors embedded in machinery can provide valuable data about equipment performance, alerting operators to potential issues before they escalate. This proactive approach not only extends the lifespan of production equipment but also increases overall operational uptime. As businesses dive deeper into 2025, adopting these innovative automation techniques will be vital for staying competitive in the fast-evolving plastic manufacturing industry. The combination of efficiency and reduced operational costs will empower companies to innovate and meet the growing demands of consumers more effectively.

As industries face increasing pressure to reduce their environmental impact, integrating biodegradable materials into mainstream manufacturing processes is emerging as a crucial strategy for 2025. According to a recent report by the Ellen MacArthur Foundation, switching to biodegradable plastics could reduce plastic waste in landfills by up to 80% over the next decade. This highlights the potential for companies to not only comply with regulatory pressures but to also align themselves with the growing consumer demand for sustainable products.

Adopting innovative plastic manufacturing techniques that utilize biodegradable materials can also drive competitive advantage. A 2022 market analysis from Grand View Research indicated that the biodegradable plastics market is expected to reach USD 23.79 billion by 2028, growing at a CAGR of 14.1%. This growth is fuelled by advancements in material science and increased investment in R&D. By integrating these materials into their processes, manufacturers can improve product lifecycle management, attract eco-conscious consumers, and position themselves favorably in a market that is progressively shifting towards sustainability.

Data-driven decision-making is revolutionizing the plastic manufacturing industry, enabling companies to leverage AI technology to fuel growth. According to a recent report by Grand View Research, the global plastic market is projected to reach $650 billion by 2025, with an increasing emphasis on smart manufacturing processes. Companies that adopt AI solutions can optimize production efficiency and minimize waste, leading to significant cost savings. For instance, predictive analytics can forecast machinery failures before they happen, reducing downtime and enhancing operational efficiency.

Tip: Implement machine learning algorithms that analyze historical production data to identify patterns and predict maintenance needs. This proactive approach can enhance productivity and lower operational costs.

Melting the traditional barriers in production methods, AI can also aid in customizing manufacturing processes to meet specific client demands. A study from McKinsey & Company highlights that manufacturers who utilize advanced analytics and AI can improve production rates by up to 20%. By streamlining the design phase and automating quality control, businesses can accelerate time-to-market for new products.

Tip: Invest in AI-driven quality inspection systems that can detect issues in real time, ensuring high standards and reducing the likelihood of errors during production. Embracing these innovative techniques will be essential for thriving in a competitive market.

880 W 9th Street

Upland, California 91786

884 W 9th Street

Upland, California 91786

886 W 9th Street

Upland, California 91786

884 W 9th Street

Upland, California 91786