As businesses strive to stay competitive in today’s fast-paced market, selecting the right injection molding services in California is a critical decision that can significantly impact productivity and product quality. According to John Smith, a renowned expert in injection molding, "Choosing the right partner for injection molding is not just about cost; it's about finding a reliable manufacturer who understands your specific needs and can deliver consistent results." This insight highlights the importance of thorough evaluation when seeking injection molding services that align with your project requirements.

In the vibrant and technologically advanced landscape of California, companies have access to numerous injection molding service providers. However, with so many options available, it can be challenging to determine which ones possess the capabilities and expertise necessary for your project. Understanding the key factors that contribute to quality injection molding services will empower businesses to make informed decisions that ensure long-term success and satisfaction.

This article will guide you through essential considerations in selecting the best injection molding services in California, from assessing technological capabilities and production processes to evaluating customer service and support. Armed with this knowledge, you'll be well-prepared to choose a partner that will help drive innovation and excellence in your manufacturing operations.

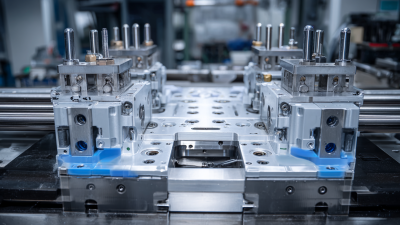

When selecting injection molding services in California, it’s essential to evaluate the industry credentials of potential partners. Key certifications can indicate a company’s adherence to industry standards and commitment to quality. For example, ISO 9001 certification demonstrates an organization's ability to consistently provide products that meet customer and regulatory requirements, which is crucial in maintaining high manufacturing standards. According to data from the Society of Plastics Engineers, more than 50% of leading injection molding companies hold ISO certifications, ensuring reliability and excellence in service delivery.

Additionally, certifications such as ISO 13485 for medical devices and IATF 16949 for automotive applications highlight specialized capabilities in producing compliant products for specific sectors. Companies with these credentials have undergone rigorous evaluations, making them more trustworthy for critical projects.

**Tips:** When assessing injection molding services, inquire about specific certifications relevant to your industry. Evaluate their experience with projects similar to yours, as a proven track record enhances confidence in their capabilities. Lastly, consider asking for client testimonials or case studies that demonstrate their adherence to quality standards and industry regulations.

This bar chart illustrates the percentage of injection molding services in California that hold key industry certifications, demonstrating the importance of credentials in selecting the best service provider.

When selecting injection molding services in California, it is crucial to analyze the cost-effectiveness of different providers. The pricing structures can vary significantly based on factors such as materials used, production volume, and turnaround times. Some companies may offer lower upfront costs but implement hidden fees that inflate the final invoice, making a detailed breakdown of quotes essential. Understanding these nuances helps businesses make informed decisions that align with their budget constraints and project needs.

Additionally, comparing pricing across various manufacturers allows for a better understanding of market standards and potential savings. Some facilities may offer bulk discounts or innovative pricing models that cater to long-term partnerships, impacting overall value. It is beneficial to engage directly with service providers to discuss specific requirements and negotiate terms that can enhance cost-effectiveness. By considering both the immediate and ongoing costs associated with injection molding services, companies can ensure they select a partner that delivers not only competitive pricing but also the quality and reliability necessary for successful manufacturing projects.

| Service Provider | Average Cost per Unit ($) | Minimum Order Quantity | Lead Time (Days) | Material Types Offered | Quality Certifications |

|---|---|---|---|---|---|

| Provider A | 1.50 | 1000 | 15 | ABS, PS, PC | ISO 9001 |

| Provider B | 2.00 | 500 | 10 | PE, PP, Nylon | ISO 13485 |

| Provider C | 1.80 | 800 | 20 | PET, TPU, PVC | ISO 9001, ISO 14001 |

| Provider D | 2.50 | 300 | 30 | PC, PBT, SAN | ISO 9001, TS 16949 |

| Provider E | 1.60 | 700 | 18 | ABS, HDPE, LDPE | ISO 9001 |

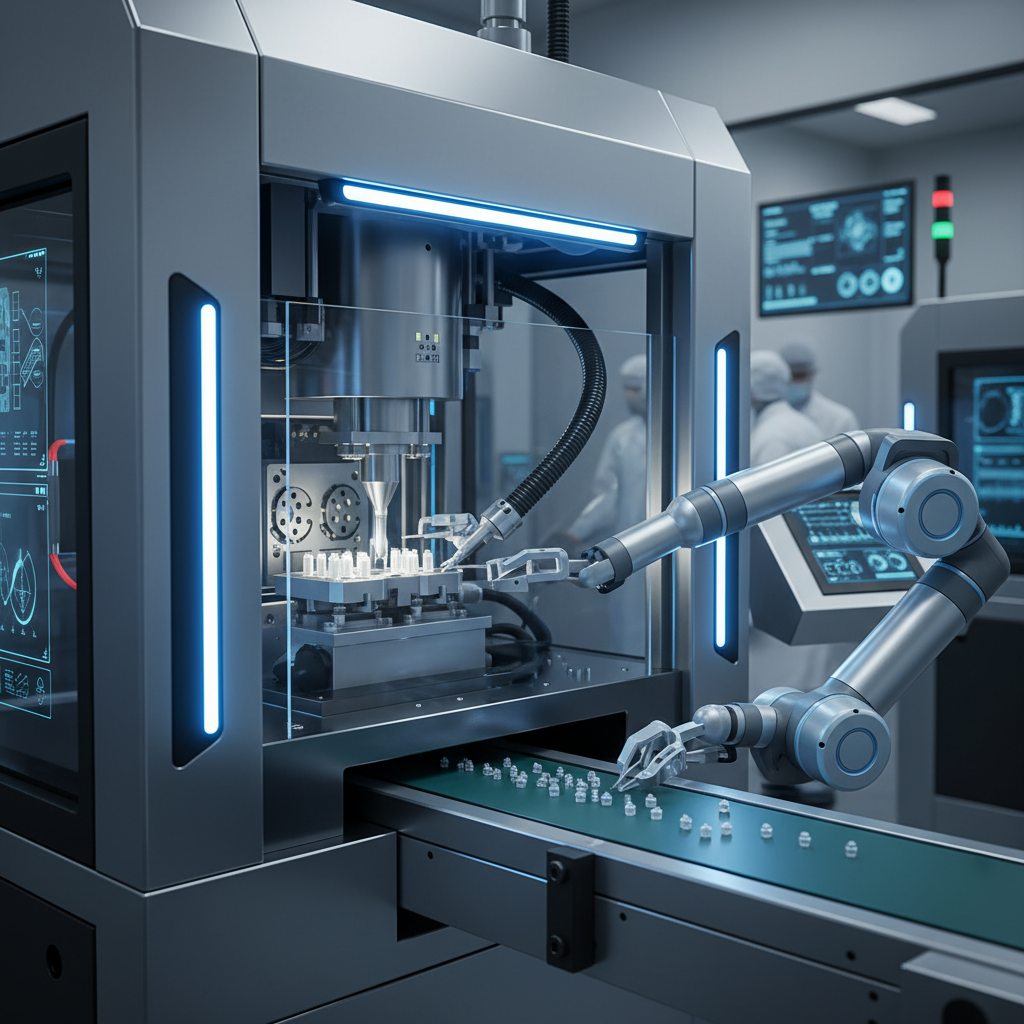

When choosing the best injection molding services in California, it's crucial to assess the technology utilized by providers. Emerging trends in injection molding machinery are reshaping the industry, reflecting a significant shift towards advanced capabilities. The global micro injection molding machine market is anticipated to grow from $551.3 million in 2025 to $759.2 million by 2032, underlining the increasing demand for precision and efficiency in production processes.

The broader plastic processing machinery market is also on the rise, projected to reach over $34.62 billion by 2032, with a CAGR exceeding 5.6% from 2025. This growth trajectory indicates that top-tier injection molding services will increasingly adopt state-of-the-art machinery to enhance their production capacity and ensure high-quality outputs. Specifically, plastic injection molding machines are evolving, with manufacturers segmenting the market based on machine type and clamping force to meet diverse industrial needs.

**Tips:** When evaluating injection molding services, inquire about the types of machinery they use and their ability to adapt to the latest technological advancements. Additionally, consider providers that offer scalable solutions to meet both current and future production demands, ensuring longevity and efficiency in your projects.

When selecting the best injection molding services in California, a critical factor to consider is the lead time associated with production. Understanding the production timeline is essential for ensuring that your project aligns with your business needs. Efficient injection molding services typically provide a clear timeline from initial design to final delivery, allowing you to plan accordingly. By inquiring about their standard lead times, you can gauge their ability to meet your deadlines and avoid potential delays that can disrupt your workflow.

Another aspect of production efficiency is the use of metrics to measure output quality and consistency. Leading services often utilize performance indicators such as cycle time, defect rates, and throughput to optimize their processes. By examining these metrics, you can discern how well a provider maintains quality while staying on schedule. Asking for detailed efficiency reports can give you insights into their operational capabilities and help you find a service that not only meets your time requirements but also commits to high-quality production standards.

When selecting the best injection molding services in California, understanding customer reviews and case studies is vital. These insights can provide a window into the quality of service and product outcomes offered by a provider. Analyzing real-world feedback enables businesses to uncover strengths and weaknesses of potential partners, ensuring informed decisions. In today’s digital age, where customer reviews can significantly impact buying choices, leveraging tools to collect and analyze this feedback is essential.

Tips: Start by visiting reputable platforms to read customer testimonials and ratings. Look for trends in feedback regarding quality, punctuality, and communication. Additionally, reach out directly to a few past clients for their experiences; firsthand accounts often reveal more than online reviews.

Another effective approach is to delve into case studies that showcase specific projects. These studies can highlight a company's expertise in handling complex molding challenges, which is crucial for your specific needs. Pay attention to the technology they employ and their approach to problem-solving, as these factors can greatly influence the efficiency and outcome of your production process.

880 W 9th Street

Upland, California 91786

884 W 9th Street

Upland, California 91786

886 W 9th Street

Upland, California 91786

884 W 9th Street

Upland, California 91786