Selecting the right plastic injection molding machine is crucial for any manufacturing operation. The performance of your machine can greatly impact productivity and cost. A suitable machine enhances efficiency and reduces waste. However, the choice can be daunting. Different machines offer various capabilities and features.

When assessing options, consider your production needs carefully. Factors include part size, material type, and expected output. Some machines excel in speed, while others prioritize precision. It’s essential to investigate each model’s specifications. Don't forget to account for maintenance and operational costs.

Your choice should reflect your unique production goals. A machine that works well in one setting may not fit another. Seek advice but rely on your judgment. Understand your requirements deeply. This process involves reflection on your existing equipment and future plans. The right decision can elevate your production potential.

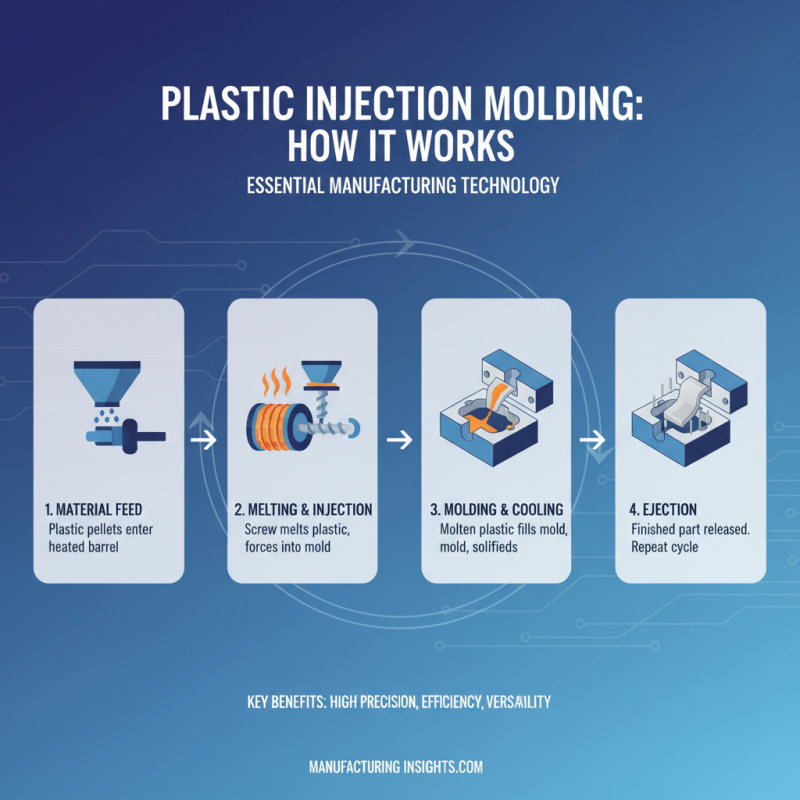

Understanding plastic injection molding machines is essential for anyone in the manufacturing industry. These machines are complex yet powerful tools used to create a variety of plastic parts. They work by injecting molten plastic into a mold, allowing for high precision and efficiency. The process may seem straightforward, but it involves several key components that must work harmoniously.

The size and capacity of the machine should match production needs. A smaller machine might save costs but could limit production volume. Conversely, a larger machine may lead to unnecessary expenses. Operators must also consider the type of plastic materials they plan to use. Each type has specific requirements for temperature and pressure, which can affect the choice of machine.

Moreover, maintenance is often overlooked. Regular upkeep ensures that machines operate effectively. Neglecting this aspect can lead to decreased efficiency and costly breakdowns. Understanding these basics helps in making informed decisions, but it requires a willingness to learn and adapt. Balancing costs, capacity, and maintenance is not easy, but it is crucial for success in using plastic injection molding machines.

Choosing the right plastic injection molding machine is crucial for efficient production. Key specifications play a vital role in this decision. One important factor is the clamping force. It determines how tightly the mold is held during injection. Machines with too little clamping force may lead to defects. It is essential to match the force with the material and part design.

Another critical specification is the injection unit. You need to consider the shot size and injection speed. The shot size must fit the part's volume. However, speed affects cycle times and part quality. A balance must be struck here. Additionally, control systems often vary. More advanced options may provide better precision.

Think about energy efficiency as well. It’s often overlooked but can lead to significant savings over time. Machines that consume less power can greatly reduce operational costs. Not all machines are built for energy efficiency, so research is necessary. Reflecting on these specifications could prevent costly mistakes later on.

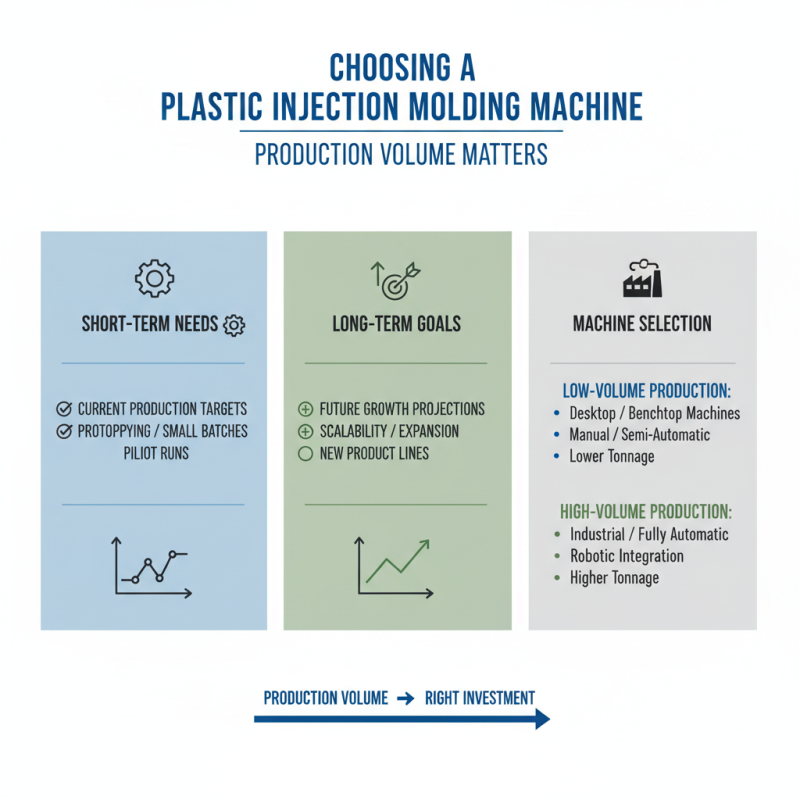

Choosing the right plastic injection molding machine hinges significantly on understanding your production volume needs. Delving into these needs helps ensure you invest wisely in machinery that meets your operational demands. Assessing production volume isn’t simply about current requirements; it requires foresight. Consider both short-term and long-term production goals.

One critical aspect is forecasting. Look at your production trends over time. Are you ramping up for a large order? Or do you expect steady demand? This impacts machine size and capacity. Think about peak periods and how they compare to average production rates.

Tips: Pay attention to cycle times. Machines with faster cycle times can boost productivity during peak seasons. Don’t underestimate the importance of flexibility. A machine that adapts to changes in your production schedule might save you headaches down the road.

You may find that initial calculations seem off. Perhaps your estimates were based on guesswork rather than data. It’s difficult, but refining your numbers is essential. Engaging with your team can help clarify production goals. Ensure everyone is on the same page about expected output.

Choosing the right plastic injection molding machine goes beyond capacity and speed. One crucial factor is material compatibility. Different materials react differently under heat and pressure. This can affect the quality of your products.

For example, thermoplastics may require specific temperature settings. They can melt and form shapes effectively. However, thermosetting plastics need careful temperature control. Choosing a machine that matches these requirements is vital. Not all machines handle every material well.

**Tip:** Always check the machine's specifications before making a choice. Look for temperature ranges and compatible materials.

Remember, different materials can cause wear and tear on machines. Some may release harmful fumes if overheated. Assess the type of materials you plan to use, and make an informed decision.

**Tip:** Test small batches with new materials to see how your machine performs. This can save you from costly mistakes. Compatibility is key to efficiency and product quality in any production line.

| Material Type | Molding Temperature (°C) | Injection Pressure (Mpa) | Cycle Time (seconds) | Machine Size Recommendation (ton) |

|---|---|---|---|---|

| Polypropylene (PP) | 180 - 230 | 70 - 90 | 20 - 30 | 80 - 120 |

| Acrylonitrile Butadiene Styrene (ABS) | 200 - 240 | 90 - 110 | 25 - 35 | 100 - 150 |

| Polyvinyl Chloride (PVC) | 160 - 200 | 80 - 100 | 30 - 40 | 90 - 130 |

| Polyethylene Terephthalate (PET) | 220 - 260 | 100 - 130 | 20 - 25 | 120 - 180 |

| Nylon (PA) | 240 - 280 | 110 - 140 | 25 - 30 | 100 - 160 |

When evaluating the cost-effectiveness and ROI of plastic injection molding equipment, it's crucial to analyze various factors. Initial purchase price is just one part of the equation. According to a recent industry report, up to 30% of total operational costs come from maintenance and downtime. Selecting a machine that balances performance and reliability can reduce these hidden costs.

Another key aspect is energy consumption. Reports indicate that newer injection molding machines can be 20-40% more energy-efficient than their predecessors. This reduction in energy costs can significantly impact the overall ROI. However, some companies overlook the energy factor during the selection process. They focus solely on initial costs, often leading to increased expenses later.

Lastly, consider the production output. A high-output machine might seem expensive, but if it reduces cycle times, the savings can add up. A study revealed that optimizing cycle time can improve ROI by 15-25%. While it may be tempting to choose the cheapest option upfront, reflecting on these factors can lead to better long-term decisions. Balancing overall costs with expected output is essential for maximizing investment in injection molding technology.

880 W 9th Street

Upland, California 91786

884 W 9th Street

Upland, California 91786

886 W 9th Street

Upland, California 91786

884 W 9th Street

Upland, California 91786