In 2025, the demand for precision plastics is expected to reach unprecedented levels, driven by advancements in manufacturing techniques and applications across various industries. A report by MarketsandMarkets highlights that the global precision plastics market is projected to grow at a CAGR of 5.8% from 2020 to 2025, reflecting the increasing reliance on these materials in sectors such as automotive, aerospace, and medical devices. This trend underscores the importance of selecting the right precision plastics tailored to specific project needs.

According to Dr. Emily Carter, a leading expert in polymer sciences, "The choice of precision plastics can significantly affect the performance and reliability of the final product." This statement encapsulates the critical role that material selection plays in achieving project success. With numerous options available, from thermoplastics to polyurethane-based compounds, understanding the unique properties and processing requirements of each material is paramount. As technology continues to evolve, so too must our approaches to sourcing and utilizing precision plastics, ensuring that we remain at the forefront of innovation and efficiency in manufacturing processes.

Precision plastics have become integral to modern manufacturing processes, influencing a wide range of industries, from automotive to healthcare. These materials provide the level of accuracy and consistency that is essential for the production of high-quality components. The right choice of precision plastics can significantly affect not only the performance of the final product but also the efficiency of the manufacturing process itself. Understanding properties such as tensile strength, thermal stability, and chemical resistance is crucial for selecting the appropriate material for specific applications.

As manufacturing continues to evolve, the demand for precision plastics is expected to grow. Trends such as automation and the increasing complexity of design specifications necessitate materials that can offer both durability and precision. Moreover, with advancements in technology, new formulations and types of precision plastics are emerging, which can enhance production capabilities while also reducing waste. Manufacturers must stay informed about these developments to make educated decisions that align with their project requirements and sustainability goals. Emphasizing the role of precision plastics in achieving these objectives is essential for maintaining competitive advantages in the ever-evolving landscape of modern manufacturing.

| Material Type | Key Properties | Applications | Cost per Kg | Availability |

|---|---|---|---|---|

| Polycarbonate | High impact resistance, optical clarity | Automotive, electronics, safety glasses | $2.50 | High |

| Acrylic | Good optical clarity, weather resistant | Signs, displays, light fixtures | $2.00 | Medium |

| Polypropylene | Chemical resistance, lightweight | Packaging, automotive components | $1.50 | High |

| Nylon | Durability, wear resistance | Industrial applications, gears | $3.00 | Medium |

| PTFE | Non-stick, chemical resistance | Seals, gaskets, bearings | $5.00 | Low |

When selecting precision plastics for your project in 2025, several key criteria should guide your decision-making process. First and foremost, it’s essential to consider the specific application's requirements. Factors such as temperature resistance, chemical compatibility, and mechanical properties play a pivotal role in determining the suitability of a material. For instance, if your project involves exposure to extreme temperatures or harsh chemicals, choosing a plastic with the necessary thermal stability and corrosion resistance will be critical to ensuring the longevity and reliability of your components.

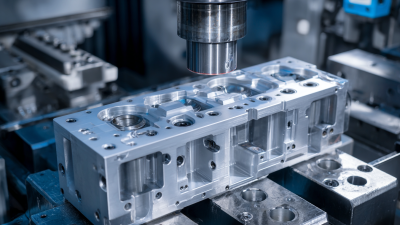

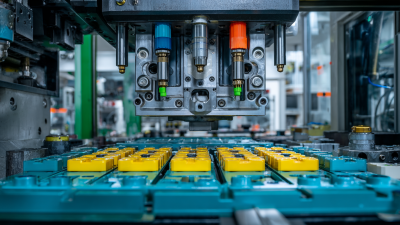

Another important criterion is the manufacturing process. Understanding the production methods available for different types of precision plastics—such as injection molding, CNC machining, or 3D printing—will help you align your material choice with the most efficient and cost-effective fabrication technique for your project. Each method has its own set of advantages and limitations, so evaluating how well a particular plastic can be processed while meeting design specifications will facilitate a smoother project development cycle. Moreover, considering factors such as scalability and lead time can further impact the overall success of your project. By carefully weighing these criteria, you can make an informed decision that enhances both functionality and performance.

When selecting precision plastics for your project in 2025, evaluating material properties like strength, flexibility, and temperature resistance is crucial. Strength refers to a material's ability to withstand applied forces without failure. According to a 2023 industry report by the Plastics Research Institute, high-performance engineering plastics, such as polycarbonate and acrylonitrile butadiene styrene (ABS), exhibit tensile strengths exceeding 80 MPa and 50 MPa, respectively. These materials ensure that components stay intact under significant stress, making them ideal for applications in automotive and aerospace industries.

Flexibility, on the other hand, relates to the material's capacity to deform under stress and return to its original shape. Flexible polymers such as thermoplastic elastomers can achieve elongation at break values of over 400%, allowing them to absorb shocks and vibrations effectively. This characteristic is particularly valuable in applications that require dynamic movement, like in consumer electronics or medical devices. Furthermore, temperature resistance is a vital factor, especially in applications where heat exposure is prevalent. A report from the International Polymer Science Association states that high-temperature resistant plastics, such as PEEK and PTFE, can maintain their mechanical properties in environments exceeding 250°C, making them suitable for industrial applications where traditional plastics would fail.

In recent years, the shift towards eco-friendly materials has significantly influenced the precision plastics industry. As environmental awareness grows, manufacturers are increasingly prioritizing sustainable sourcing and production processes. This trend is not just a fleeting moment; it reflects a broader commitment within the industry to reduce carbon footprints and minimize waste. Innovative bioplastics, derived from renewable resources, are emerging as viable alternatives to traditional petroleum-based plastics. These materials not only lessen environmental impact but also offer comparable performance characteristics suitable for precision applications.

Moreover, the integration of recycled materials into precision plastics production is making strides. By utilizing post-consumer plastics, companies can contribute to a circular economy while maintaining the integrity and functionality required in high-precision industries. This approach not only conserves raw materials but also appeals to environmentally conscious consumers and clients. As businesses adapt to these eco-friendly practices, understanding the properties and applications of these materials will be crucial for ensuring that projects meet both performance standards and sustainability goals. Embracing these industry trends allows companies to stay competitive in the evolving landscape of precision plastics in 2025 and beyond.

When selecting precision plastics for your project, a crucial aspect to consider is the cost-benefit analysis, which involves striking a balance between quality and budget. High-quality plastics often come at a premium price, but their durability and performance can significantly influence the overall success of your project. It is essential to evaluate the specific requirements of your application—this includes the environmental conditions, mechanical stress, and the expected lifespan of the product. Investing in superior materials can reduce the risk of failure and unforeseen costs later on, making it a wise long-term investment for many projects.

On the other hand, staying within budget constraints is also critical, especially in large-scale projects or when resources are limited. Conducting a thorough analysis helps identify which properties of plastics are non-negotiable for your specific applications. For instance, while you may prioritize certain qualities like temperature resistance or chemical stability, you might find that opting for alternative materials with slightly lower performance could be more cost-effective without compromising essential functionalities. By strategically comparing various options, you can achieve a thoughtful compromise that meets both quality standards and financial limits.

880 W 9th Street

Upland, California 91786

884 W 9th Street

Upland, California 91786

886 W 9th Street

Upland, California 91786

884 W 9th Street

Upland, California 91786