The demand for plastic molding continues to grow in various industries. Reports show that the global plastic injection molding market is projected to reach $427.6 billion by 2027. This growth highlights the importance of adopting digital best practices within plastic molding techniques.

Digital technologies have transformed traditional molding processes. Integrating advanced software can streamline production and enhance accuracy. However, many companies struggle with implementing these technologies effectively. A recent survey indicated that only 30% of companies leverage digitization in their molding processes. This gap suggests a significant opportunity for improvement.

While digital solutions can elevate efficiency, they also raise challenges. Companies must invest time and resources in training staff. Resistance to change can hinder progress. It is crucial to address these challenges to unlock the full potential of digitalization in the plastic molding industry. Companies that embrace these practices may lead the way in innovation and profitability.

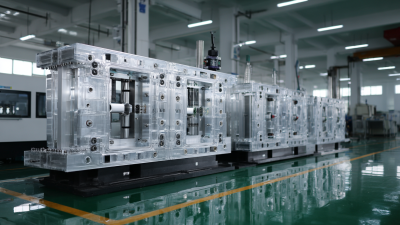

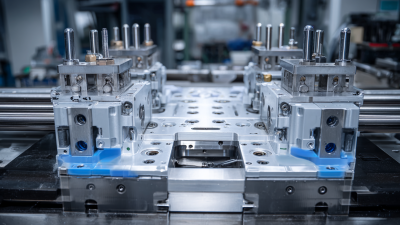

Plastic molding techniques are essential in digital manufacturing. These processes include injection molding, blow molding, and rotational molding. Each technique has unique characteristics and applications. Injection molding is efficient for mass production of detailed parts. It allows intricate designs but can have high initial costs.

Blow molding, on the other hand, is focused on hollow objects. It is often used for containers and bottles. While this technique can produce lightweight items, it may not suit complex geometries. The flexibility of rotational molding allows for larger parts, yet it typically lacks precision.

Digital technology enhances all these methods. CAD software designs parts with ease. Virtual simulations help predict potential issues. However, not all designs translate perfectly to physical products. Iteration is vital in refining these designs. Mistakes can happen in scaling up prototypes. Continuous learning from errors is necessary to improve outcomes in plastic molding.

Digital technology has transformed plastic molding processes in significant ways. One prominent benefit is increased precision. Advanced software tools allow for detailed simulations before actual production. This reduces waste and minimizes errors. Errors in molding can lead to costly reworks. With digital solutions, manufacturers can foresee potential problems and address them.

Another advantage is enhanced communication across teams. Digital platforms enable real-time updates and discussions. This agility can speed up project timelines. However, not all teams are equipped for this transition. Training staff is essential yet often overlooked. There may be resistance to change from traditional methods. Adaptation can take time, leading to initial disruptions.

Moreover, data analytics can optimize production efficiency. Analyzing machine performance helps identify bottlenecks. Yet, relying solely on data may overlook human creativity. Human intuition is still vital in problem-solving. Balancing technology with human insight is a challenge many face. Finding the right synergy can improve outcomes significantly. As the industry evolves, reflection on these aspects is crucial.

Digital tools play a crucial role in plastic molding design. Software for Computer-Aided Design (CAD) allows engineers to create detailed models. According to industry reports, over 70% of manufacturers use CAD in their processes. It streamlines design and reduces errors. However, not all designs translate seamlessly into production. Many designers face challenges in optimizing mold flow.

Simulation software enables designers to visualize the molding process. This technology predicts how plastic will flow in the mold. A study found that simulations can cut prototype costs by up to 50%. Yet, accuracy depends on the quality of the input data. Inadequate data can lead to poor design choices. Designers need to be mindful of this when using such tools.

Collaborative platforms also enhance workflow. Teams can share designs in real-time and provide feedback. A survey indicated that 60% of industry professionals view collaboration as essential. Despite its benefits, communication gaps still exist. Sometimes, teams misinterpret feedback, leading to design inconsistencies. Each of these digital tools presents unique advantages and challenges. Careful implementation is necessary to maximize their effectiveness.

| Digital Tool/Software | Key Feature | Advantages | Application Area |

|---|---|---|---|

| CAD Software | 3D Modeling | Enhanced design accuracy | Design Development |

| Simulation Software | Molding Simulation | Predicts defects and optimizes designs | Process Optimization |

| PLM Software | Lifecycle Management | Improves collaboration and reduces time to market | Project Management |

| CNC Programming Software | Tool Path Generation | Enhances machining precision | Manufacturing |

| ERP Software | Resource Planning | Streamlines operations and reduces costs | Supply Chain Management |

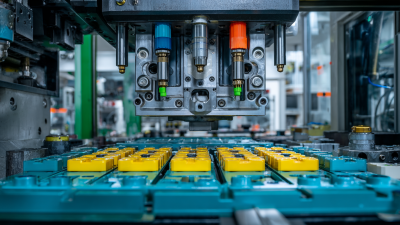

Digital innovations are transforming plastic molding techniques. By integrating smart technologies, manufacturers can optimize their processes. For instance, using real-time data analytics helps predict mold performance. Monitoring temperature and pressure levels can enhance product quality. Yet, many still rely on outdated methods. Adapting to new practices can pose challenges for traditional manufacturers.

Another effective strategy is 3D modeling. Digital twins allow for virtual testing of designs before production. This reduces waste and improves efficiency. However, some designers may find it hard to trust technology. They might prefer hands-on techniques that have worked in the past. Embracing change can be uncomfortable, yet it is necessary for growth.

Training staff on digital tools is equally important. Employees need to understand how to interpret data correctly. Misinterpretation of data could lead to production errors. Moreover, investment in training might seem costly upfront. Yet, the long-term benefits justify this expense. Fostering a culture of continuous learning is vital for staying competitive.

The future of digital plastic molding technologies is both exciting and complex. Advancements in artificial intelligence and machine learning are shaping production processes. Real-time data collection enhances material selection and reduces waste. This improvement is crucial for sustainability in manufacturing. However, integrating these technologies can be challenging. Many companies struggle with the transition from traditional methods.

Additive manufacturing techniques are also gaining traction. They allow for quicker prototyping and more intricate designs. This flexibility meets the evolving demands of consumers. Yet, companies need to rethink their workflows. Adopting new techniques might disrupt established practices. The learning curve can be steep.

The role of simulation tools is increasingly important. They help predict how materials will behave under different conditions. However, accuracy varies, and results must be interpreted cautiously. Over-reliance on simulations can lead to errors. Companies must be prepared to iterate and refine their processes. Balancing innovation with reliability will be key as digital molding technologies evolve.

880 W 9th Street

Upland, California 91786

884 W 9th Street

Upland, California 91786

886 W 9th Street

Upland, California 91786

884 W 9th Street

Upland, California 91786