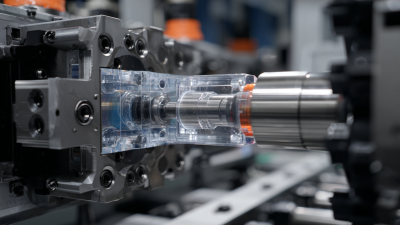

When it comes to achieving optimal production efficiency in the manufacturing industry, selecting the right injection molding materials is crucial. The choice of materials can significantly influence not only the quality and durability of the final product but also the overall cost-effectiveness and turnaround time of the production process. In this blog, we will explore five essential tips that will guide you through the complexities of choosing the best injection molding materials for your specific needs. From understanding the characteristics of different materials to considering factors like production volume and processing techniques, these insights will empower you to make informed decisions that enhance operational performance. Whether you're a seasoned professional or new to the injection molding arena, our practical advice will help you streamline your material selection process and achieve superior results.

When selecting the right injection molding materials, it's crucial to understand the variety of options available in the market. High-performance polyamides, for instance, are projected to dominate the market, with a valuation expected to reach $2.72 billion by 2029. This growth is driven by the material's versatility and its applications across industries such as automotive and electronics.

Polyamides like PA 11 and PA 12 are especially noteworthy for their excellent mechanical properties and resilience, making them ideal for products that require strength and durability.

Polyamides like PA 11 and PA 12 are especially noteworthy for their excellent mechanical properties and resilience, making them ideal for products that require strength and durability.

In addition to polyamides, the metal injection molding sector is also witnessing significant growth, with market size predictions indicating expansion in the coming years. It is segmenting into various types, including stainless steel and other alloys, which offer distinctive benefits such as enhanced strength and resistance to corrosion. As the global injection molding machines market is anticipated to reach approximately $25.78 billion by 2033, it’s essential for manufacturers to stay abreast of material advancements to optimize production efficiency. Understanding the properties and market trends of these materials can significantly impact decision-making processes in manufacturing.

When selecting injection molding materials, understanding key properties is crucial for enhancing production efficiency. One of the primary factors to consider is the material's strength and durability. Materials like ABS and polycarbonate offer excellent impact resistance, making them suitable for applications requiring high durability. Moreover, the tensile strength of the material will determine its ability to withstand deformation under stress during production processes.

Another vital property is thermal stability. Different materials react variably to heat, affecting both the molding process and the final product's quality. For instance, materials like nylon and polyester have higher thermal resistance, which can be advantageous in applications exposed to elevated temperatures. Additionally, it is essential to evaluate the material's flow characteristics. A material with good flow ability can fill molds more efficiently, reducing cycle times and improving overall production efficiency. Engaging in careful analysis of these properties can lead to more informed decisions, resulting in better performance and reduced waste in the production line.

When it comes to injection molding, selecting the right materials can make a significant impact on production efficiency and cost-effectiveness. A crucial aspect of this selection process is assessing the trade-off between cost and performance. According to a report by Grand View Research, the global market for injection molding materials is expected to reach $297.7 billion by 2027, underscoring the industry's reliance on high-quality materials that optimize efficiency without breaking the budget.

In practice, manufacturers often face challenges when balancing material costs with performance attributes such as strength, durability, and resistance to environmental factors. For instance, while engineering plastics may come with a higher initial price tag, their superior properties can lead to lower maintenance costs and increased product lifespans. According to the Plastic Industry Association, plastic materials account for about 40% of all manufacturing costs in the automotive sector; therefore, making informed choices can significantly reduce overall production expenses while enhancing end-product quality. By carefully evaluating and comparing different materials, manufacturers can achieve a sweet spot where both cost and performance meet their operational demands efficiently.

In the realm of injection molding, the choice of materials extends beyond mechanical performance to encompass significant environmental considerations. A recent report from the Plastics Industry Association highlights that nearly 35% of plastic waste in landfills originates from manufacturing processes, making sustainable material choices imperative. Companies are increasingly turning to bio-based polymers, such as polylactic acid (PLA), which can reduce the carbon footprint significantly. For instance, using PLA instead of conventional plastics can lower greenhouse gas emissions by up to 68% over the material’s lifecycle, according to a study by the European Bioplastics Association.

Moreover, the move towards recyclable materials within the injection molding sector is gaining traction. Research from the American Society of Plastics Engineers (ASPE) indicates that adopting recyclable materials can lead to a 50% reduction in energy consumption during production processes. As eco-conscious consumers push for sustainability, manufacturers who prioritize materials with lower environmental impacts not only comply with regulatory pressures but also gain a competitive edge in the marketplace. By selecting materials that minimize ecological harm, companies can drive both production efficiency and sustainability in their operations.

| Material Type | Strength | Temperature Resistance (°C) | Recyclability | Environmental Impact |

|---|---|---|---|---|

| Polyethylene (PE) | Moderate | 80 | Yes | Low |

| Polypropylene (PP) | Good | 100 | Yes | Moderate |

| Acrylonitrile Butadiene Styrene (ABS) | High | 80 | Limited | High |

| Polycarbonate (PC) | Very High | 130 | No | Moderate |

| Thermoplastic Elastomers (TPE) | Good | 90 | Yes | Low |

Selecting the right injection molding materials is crucial for optimizing production efficiency. To ensure that the materials meet your specific production needs, it's essential to conduct thorough testing and evaluation.

First, consider implementing mechanical testing to assess the tensile strength and durability of the materials. This will help you determine if the material can withstand the stress and conditions it will face during production. Additionally, thermal analysis can provide valuable insights into how the materials behave under extreme temperatures, enabling you to select the most suitable options for your manufacturing processes.

Next, don't overlook the importance of compatibility testing. Evaluating how different materials interact with your existing production processes and equipment can prevent costly issues down the line. By establishing a robust testing framework, you can ensure that your chosen materials lead to smoother operations and enhanced production efficiency overall.

880 W 9th Street

Upland, California 91786

884 W 9th Street

Upland, California 91786

886 W 9th Street

Upland, California 91786

884 W 9th Street

Upland, California 91786