The landscape of manufacturing has undergone a transformative shift, particularly within the realm of plastic mold makers, who play a pivotal role in the production of intricate parts and components across various industries. According to a report by MarketsandMarkets, the global plastic injection molding market is projected to grow from USD 276.73 billion in 2021 to USD 414.40 billion by 2026, reflecting a compound annual growth rate (CAGR) of 8.5%. This accelerated growth is driven by advancements in technology, materials, and automation, prompting plastic mold makers to innovate continually.

The integration of smart manufacturing practices, alongside the adoption of sustainable materials, is reshaping their traditional operations. As industries increasingly prioritize efficiency and environmental responsibility, the evolution of plastic mold makers becomes essential in meeting the demands of a rapidly changing market.

The history of plastic mold making reveals a significant transformation from traditional handcrafted methods to modern digital solutions that have revolutionized the industry. Initially, mold makers relied on basic materials and manual techniques, such as wood or simple metal molds, which limited precision and production efficiency. Craftsmen would painstakingly carve molds by hand, leading to longer lead times and higher costs, which were impractical for mass production. As demand for plastic products surged in the mid-20th century, the need for more efficient and precise manufacturing processes became apparent.

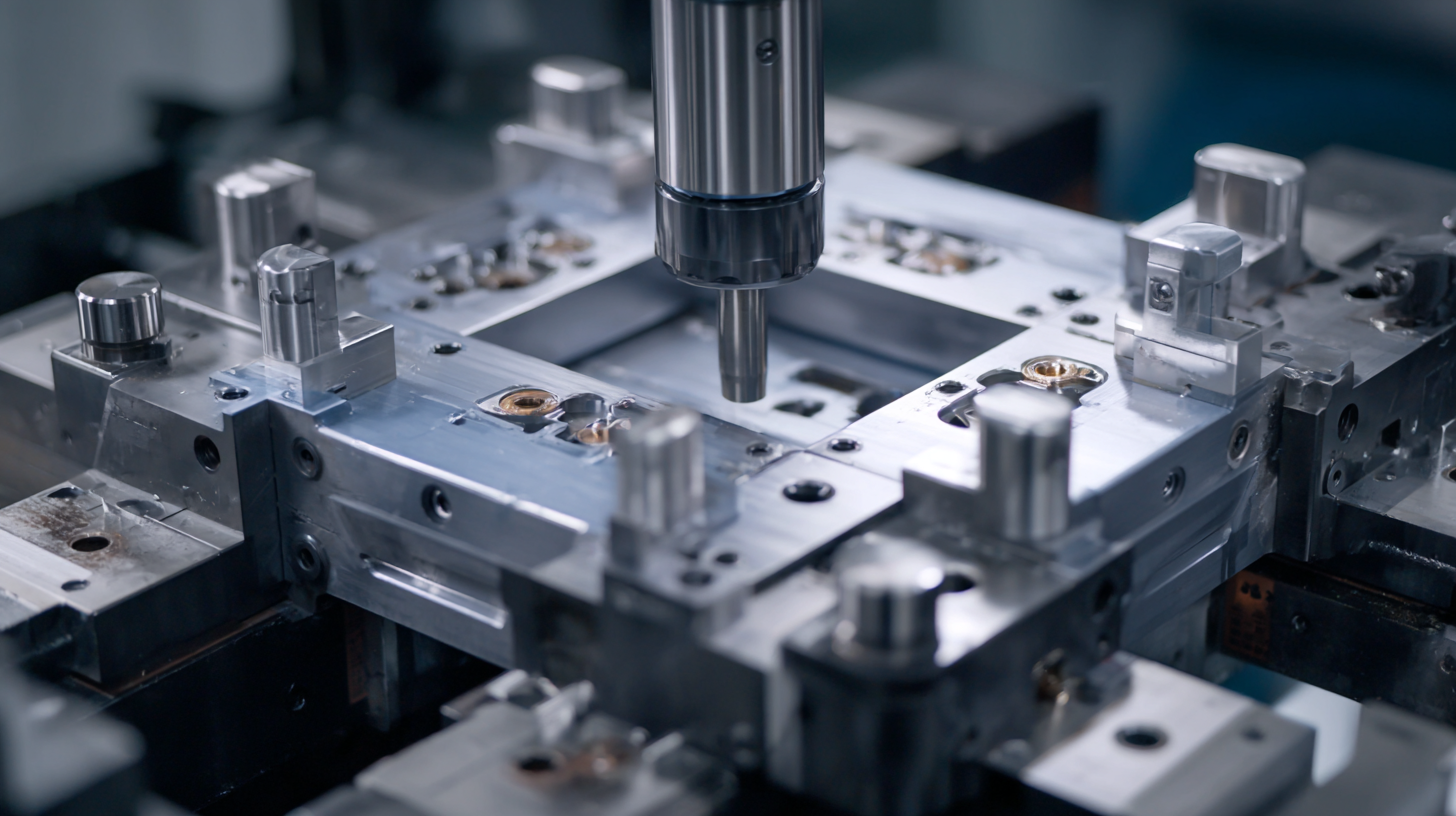

The introduction of computer-aided design (CAD) and computer numerical control (CNC) machining marked a turning point in the evolution of plastic mold making. These digital solutions allow for intricate designs and enhancements, enabling mold makers to create complex shapes with minimal human intervention. Moreover, advancements such as 3D printing and additive manufacturing have further accelerated mold production, reducing waste and time significantly.

Today, mold makers harness these technologies not only to improve quality but also to respond quickly to market changes, illustrating the ongoing evolution from traditional craftsmanship to cutting-edge innovations in the manufacturing landscape.

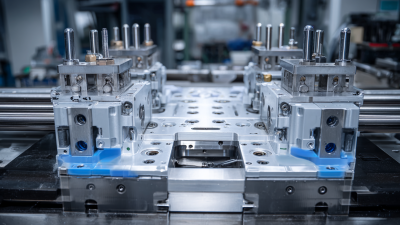

The landscape of plastic mold design and production is undergoing a significant transformation, driven by the emergence of innovative technologies. One key advancement is the adoption of additive manufacturing techniques, which enable the rapid prototyping and production of complex mold geometries. According to a report by MarketsandMarkets, the global 3D printing market in manufacturing is expected to reach $34.8 billion by 2024, highlighting the increasing reliance on these technologies in the production process. This shift not only reduces lead times but also minimizes material waste, making it a more sustainable approach to mold making.

Furthermore, advancements in automation and artificial intelligence are optimizing production efficiency. The integration of smart factories, leveraging IoT devices, allows for real-time monitoring and predictive maintenance of equipment. A study by McKinsey indicates that smart manufacturing can increase productivity by up to 20%. This technological evolution ensures that plastic mold makers can enhance their operational processes, improve quality control, and accelerate time-to-market. As these innovations continue to shape the industry, the future of plastic mold design and production looks increasingly promising and efficient.

This chart showcases the percentage adoption of emerging technologies in plastic mold design and production processes over the past five years.

Sustainability in plastic mold making has become a focal point as the industry adapts to increasing environmental concerns. Innovations such as bioplastics, which decompose more easily than traditional polymers, are leading the charge in reducing the environmental footprint of production processes. Additionally, advancements in mold design technology have enabled manufacturers to create more efficient molds that minimize waste during the production process, thus contributing to overall sustainability goals.

Tips for eco-friendly practices in plastic mold making include selecting sustainable materials that can be recycled or are biodegradable. Consider using energy-efficient machinery to reduce power consumption and lower carbon emissions. Moreover, implementing a closed-loop system in your manufacturing process can significantly reduce waste by reintroducing scrap material back into production.

Companies are also exploring cleaner production techniques, such as using water-based lubricants instead of petroleum-based options, and investing in renewable energy sources to power their facilities. These strategies not only enhance sustainability but also often lead to cost savings in the long run, proving that eco-friendly practices and profitability can go hand in hand in the plastic mold making industry.

| Innovation Area | Description | Environmental Impact | Adoption Rate (%) |

|---|---|---|---|

| Biodegradable Materials | Use of materials that can decompose naturally, reducing landfill waste. | Reduces plastic waste and environmental pollution. | 35% |

| Energy-Efficient Machinery | Machines that consume less energy during the molding process. | Lowers carbon footprint in manufacturing. | 50% |

| Recycling Systems | Systems that allow scrap materials to be reused in production. | Reduces raw material consumption and waste. | 60% |

| 3D Printing Technologies | Additive manufacturing that minimizes material waste. | Significantly lowers waste produced during manufacturing. | 40% |

| Closed-Loop Production | Manufacturing process that minimizes waste by reusing materials. | Promotes sustainable practices and reduces environmental strain. | 45% |

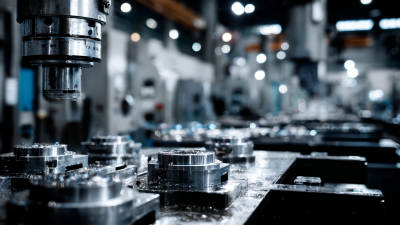

The integration of artificial intelligence (AI) in mold manufacturing is reshaping the industry, driving innovation, and enhancing efficiency like never before. According to a report by MarketsandMarkets, the global AI in manufacturing market is expected to reach $16.7 billion by 2026, growing at a CAGR of 49.5% from 2021. This exponential growth underscores the critical role that AI is playing in optimizing production processes. Advanced algorithms can analyze vast datasets to predict maintenance needs, reducing downtime, and improving overall productivity in mold making.

One significant innovation is the use of AI for design optimization. By leveraging machine learning algorithms, manufacturers can generate molds with complex geometries that are tailored for specific applications, which traditional methods might not achieve efficiently. This not only accelerates the design phase but also enhances the quality of the final product. A study by Deloitte highlights that manufacturers utilizing AI technologies can improve operational efficiency by up to 30%, translating into notable cost savings and faster time-to-market.

**Tips:** To fully capitalize on AI in mold manufacturing, consider investing in employee training programs that focus on AI technologies. Additionally, integrating AI solutions into your existing systems can dramatically streamline workflows, enabling real-time decision-making and predictive analytics. Embrace these advancements to stay competitive in the evolving manufacturing landscape.

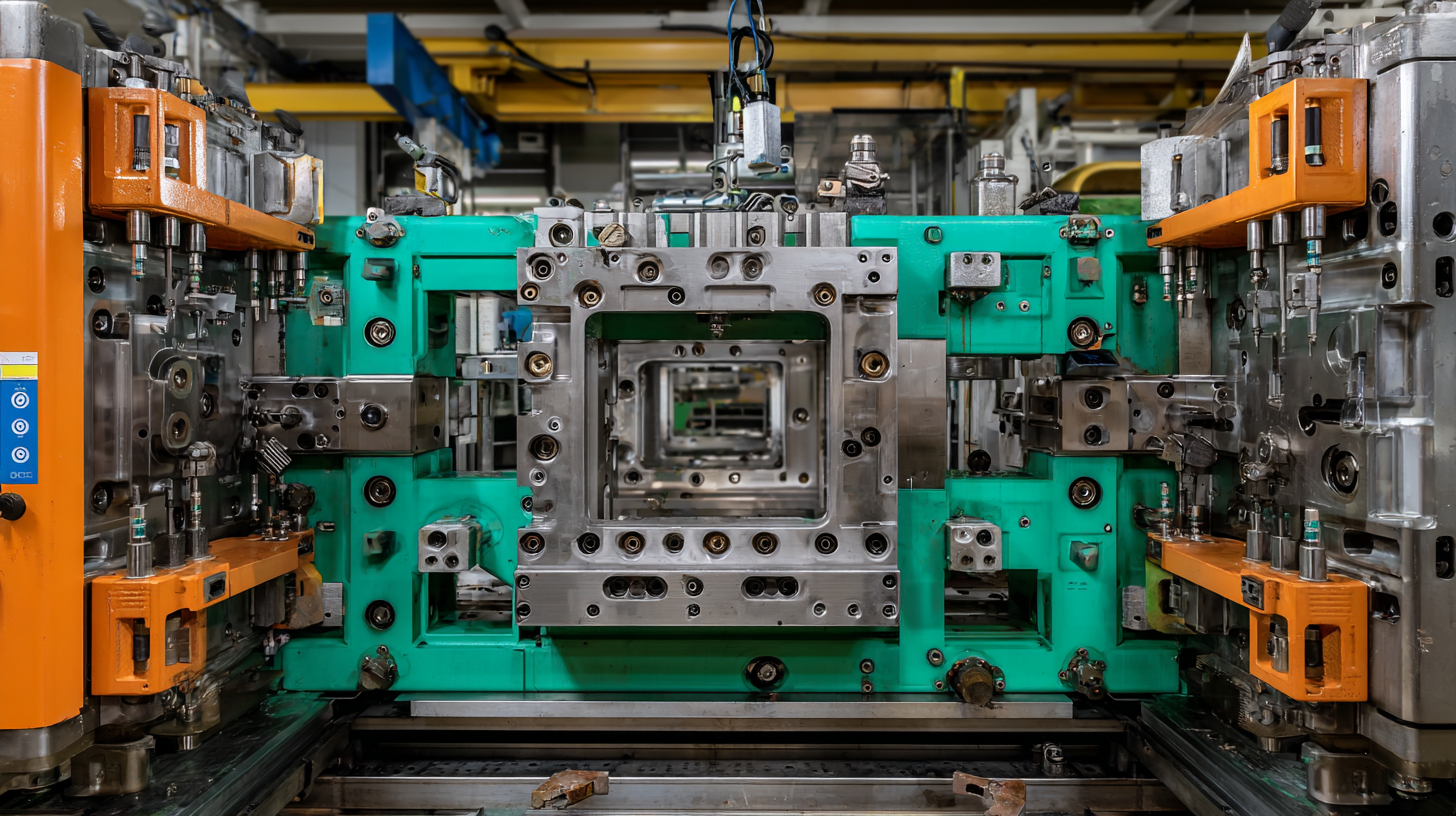

The landscape of plastic mold making is undergoing a significant transformation propelled by the principles of Industry 4.0 and the implementation of smart manufacturing techniques. At the core of this evolution is the integration of advanced technologies such as the Internet of Things (IoT), artificial intelligence (AI), and additive manufacturing. These innovations facilitate real-time data collection and analysis, enabling mold makers to optimize production processes, enhance efficiency, and reduce waste. As a result, manufacturers can swiftly respond to market demands while maintaining high-quality standards.

Moreover, digital twins and simulation technologies are becoming integral to mold design and production. By creating virtual replicas of molds, manufacturers can predict performance and identify potential issues before physical production begins. This advance not only shortens the design cycle but also fosters more creative approaches to mold design and manufacturing. As the industry leans towards more automated and data-driven processes, the role of traditional mold makers is evolving, highlighting the necessity for skill development in digital tools and smart technologies to keep pace with these rapid changes.

880 W 9th Street

Upland, California 91786

884 W 9th Street

Upland, California 91786

886 W 9th Street

Upland, California 91786

884 W 9th Street

Upland, California 91786