In the rapidly evolving landscape of manufacturing, the role of a plastic mold maker has transcended traditional boundaries, becoming a pivotal force in innovation across various industries. According to a report by MarketsandMarkets, the global plastic injection molding market is projected to reach USD 342.5 billion by 2026, growing at a CAGR of 5.5%. This growth is driven by an increasing demand for lightweight materials in automotive, electronics, and consumer goods sectors. As manufacturers seek to optimize production processes and enhance product quality, advancements in digital technologies such as 3D printing, automation, and data analytics are reshaping the plastic mold making industry. Embracing these innovations not only streamlines operations but also offers bespoke solutions tailored to specific requirements, ultimately transforming how industries approach product development and manufacturing efficiency.

The traditional plastic mold making industry is currently grappling with several challenges that threaten its effectiveness and efficiency. According to a recent report by MarketsandMarkets, the global mold market is projected to reach $25.34 billion by 2026, driven by increasing demand across various sectors, particularly automotive and consumer goods. However, traditional techniques often result in longer lead times and less flexibility in design, causing manufacturers to struggle in keeping up with rapid market changes and consumer preferences.

One of the primary issues is the increasing complexity of product designs. As noted by Deloitte, approximately 55% of manufacturers have reported challenges in meeting the rising expectations for customizability and quick turnarounds. Additionally, conventional mold making processes are frequently associated with high material waste and labor costs. The World Economic Forum highlighted that nearly 30% of total manufacturing costs can be attributed to inefficiencies in production processes, including mold design. This not only affects profit margins but also contributes to a growing need for sustainable practices in the industry. The evolution of digital technologies and automated solutions is essential for addressing these challenges, ensuring that the plastic mold making sector can adapt and thrive in an increasingly competitive market.

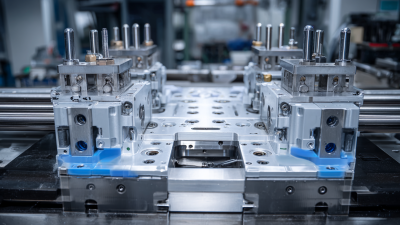

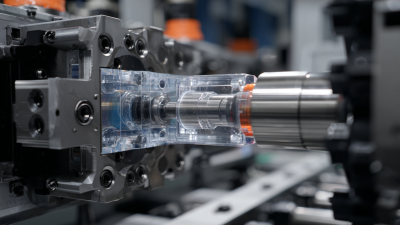

Emerging technologies are fundamentally reshaping the landscape of plastic mold production, driving efficiency and increasing precision in the manufacturing process. Advanced techniques such as 3D printing, computer numerical control (CNC) machining, and digital simulation are streamlining mold design and production. With the introduction of additive manufacturing, manufacturers can now create complex mold geometries that were previously impossible, reducing production time and cost significantly. This technology not only enhances design capabilities but also allows for rapid prototyping, enabling companies to bring their products to market faster.

Moreover, Industry 4.0 is playing a crucial role in revolutionizing plastic mold making. The integration of IoT (Internet of Things) devices into the production process allows for real-time monitoring and data analysis, improving the accuracy and efficiency of mold production. Predictive maintenance enabled by AI algorithms can foresee equipment failures before they occur, minimizing downtime and maximizing productivity. As these technologies continue to evolve, they are not just optimizing plastic mold making but are also paving the way for tailored solutions that meet the demands of diverse industries, from automotive to consumer electronics.

| Technology | Impact on Production | Benefits | Challenges |

|---|---|---|---|

| 3D Printing | Rapid prototyping of molds | Reduced lead time, design flexibility | Material limitations, surface finish quality |

| Smart Manufacturing | Automated mold production | Increased efficiency, reduced labor costs | High initial investment, need for skilled workforce |

| Simulation Software | Design validation and optimization | Enhanced design accuracy, material usage optimization | Complexity of software, learning curve |

| Additive Manufacturing | Production of complex geometries | Design freedom, reduced waste | Slower production rates, material costs |

| IoT Integration | Real-time monitoring of production | Proactive maintenance, enhanced data collection | Security concerns, data management |

Sustainability has become a central theme in plastic mold manufacturing, as industries strive to balance efficiency with environmental responsibility. The traditional processes often lead to significant waste and pollution. However, innovative solutions are emerging that focus on reducing the environmental impact while maintaining high productivity. Implementing advanced materials that are designed for recyclability can substantially decrease the carbon footprint of the manufacturing process.

Sustainability has become a central theme in plastic mold manufacturing, as industries strive to balance efficiency with environmental responsibility. The traditional processes often lead to significant waste and pollution. However, innovative solutions are emerging that focus on reducing the environmental impact while maintaining high productivity. Implementing advanced materials that are designed for recyclability can substantially decrease the carbon footprint of the manufacturing process.

To enhance sustainability in plastic mold making, manufacturers can adopt practices such as using biodegradable plastics and incorporating energy-efficient machinery. Additionally, companies should consider the entire lifecycle of their products by redesigning processes to minimize waste. One effective tip is to conduct a thorough analysis of the supply chain to identify areas where sustainability can be improved, such as sourcing materials from eco-friendly suppliers or optimizing logistics to reduce emissions.

Furthermore, embracing technology plays a pivotal role in driving sustainable practices. Automation and smart manufacturing systems can maximize resources and minimize waste. Manufacturers can leverage data analytics to monitor usage and implement changes that improve efficiency. Regular training sessions for staff on sustainable practices ensure that everyone is committed to reducing environmental impact, which is vital for the future of innovation in this industry.

The integration of automation into plastic mold making is ushering in a new era of efficiency and precision. According to a report by Markets and Markets, the global market for automated injection molding equipment is projected to reach $10 billion by 2025, reflecting a compound annual growth rate (CAGR) of 8.0%. This shift not only demonstrates the industry's commitment to innovation but also highlights how automation significantly reduces cycle times and production costs.

Automation technologies, such as robotic arms and advanced software solutions, enhance accuracy while minimizing human error. A study by Deloitte indicates that companies adopting automation in mold making have seen efficiency gains of up to 30%, allowing them to respond more rapidly to market demands. With improved maintenance predictive analytics enabled by IoT (Internet of Things) devices, mold makers can reduce downtime and enhance overall equipment effectiveness (OEE) by up to 20%. As industries evolve, the role of automation will be pivotal in shaping a more responsive and sustainable future in plastic mold making.

The landscape of plastic mold innovations is rapidly evolving, driven by advancements in technology and shifting industry demands. According to a report by MarketsandMarkets, the global plastic injection molding market is projected to reach $388.5 billion by 2027, growing at a CAGR of 5.3% from 2022. This growth reflects the increasing need for lightweight, durable components across various sectors, including automotive, consumer goods, and medical devices. Innovations in materials and processing technologies are enabling manufacturers to produce complex geometries with improved precision and efficiency.

One of the most significant trends shaping the future of plastic mold making is the integration of automation and smart manufacturing techniques. The adoption of Industry 4.0 technologies, such as IoT and AI, is streamlining operations and enhancing productivity in mold production. According to a report from Grand View Research, the smart manufacturing market is expected to reach $537 billion by 2025, with a substantial portion derived from the plastics sector. Furthermore, the rise of sustainable practices, driven by consumer demand and regulatory pressures, is pushing companies to innovate in eco-friendly materials and processes, further transforming the industry landscape.

880 W 9th Street

Upland, California 91786

884 W 9th Street

Upland, California 91786

886 W 9th Street

Upland, California 91786

884 W 9th Street

Upland, California 91786