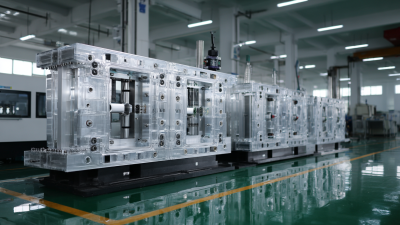

The plastic part manufacturing industry is undergoing a significant transformation driven by innovative technologies and sustainable practices. According to a report by Grand View Research, the global plastic injection molding market alone is expected to reach $392.52 billion by 2027, growing at a CAGR of 5.2%. This surge in demand is pushing manufacturers to adopt advanced methods such as 3D printing and automation to enhance efficiency and reduce waste. Additionally, as sustainability becomes paramount, many companies are exploring bioplastics and environmentally friendly materials, aligning with the Circular Economy principles emphasized in the Ellen MacArthur Foundation’s reports. This evolution not only addresses the growing consumer demand for sustainable products but also enhances the competitiveness of plastic part manufacturing against traditional materials and processes. As the industry gears up for the future, understanding these innovations will be crucial for stakeholders aiming to thrive in this dynamic landscape.

The landscape of plastic part manufacturing is undergoing a profound transformation, particularly due to the advent of emerging 3D printing technologies. According to a report by SmarTech Analysis, the global market for 3D printed plastic parts is expected to reach $7 billion by 2025, driven by industries such as automotive, aerospace, and healthcare. The ability to produce complex geometries with reduced material waste makes 3D printing not only a cost-effective solution but also a sustainable one, aligning with the increasing global emphasis on environmental responsibility.

Additionally, advancements in polymer materials, including high-performance thermoplastics and bio-based filaments, are enhancing the capabilities of 3D printing. A study published in the Journal of Material Science highlights that these innovations allow manufacturers to tailor the properties of plastic parts to specific applications, improving durability and functionality. As companies leverage these technologies, we can expect to see a significant shift towards more agile manufacturing processes, minimizing lead times and enabling rapid prototyping. This revolutionary approach is positioning 3D printing as a cornerstone for the future of plastic part production, highlighting its potential to redefine manufacturing paradigms.

| Technology Type | Material Used | Production Speed (Parts/hour) | Precision (mm) | Applications |

|---|---|---|---|---|

| Fused Deposition Modeling (FDM) | PLA, ABS | 20-30 | 0.1-0.5 | Prototyping, Hobbyist Projects |

| Selective Laser Sintering (SLS) | Nylon, TPU | 5-30 | 0.1-0.3 | Functional Parts, Small Batches |

| Stereolithography (SLA) | Resins | 10-20 | 0.05-0.1 | Highly Detailed Prototypes, Jewelry |

| Multi Jet Fusion (MJF) | Nylon | 25-100 | 0.1-0.3 | Production Parts, Functional Testing |

| Bound Metal Deposition (BMD) | Metal-Infused Polymers | 5-15 | 0.1-0.2 | Metal Parts, Complex Geometries |

The plastic manufacturing industry is undergoing a significant transformation driven by sustainability trends, particularly in the realm of biodegradable plastics and the circular economy. Reports from the Global Bioplastics Alliance indicate that the production capacity of bioplastics is anticipated to reach 2.43 million tons by 2024, a substantial increase from previous years. This shift towards renewable materials reflects a growing consumer demand for environmentally friendly solutions, with 72% of consumers considering sustainable packaging essential according to a recent survey by Packaging Insights.

Another pivotal element in this transition is the concept of the circular economy, which emphasizes the importance of reusing materials and reducing waste. Research from the Ellen MacArthur Foundation highlights that transitioning to circular systems could unlock $4.5 trillion in economic benefits by 2030. By adopting sustainable practices, manufacturers can not only improve their brand image but also enhance operational efficiency through resource recovery and waste management.

Tip: Evaluate your current supply chain. Consider integrating suppliers that focus on sustainable practices and products to foster a stronger commitment to circularity. Implementing small changes, like using recycled materials or biodegradable alternatives, can significantly impact your sustainability goals.

The development of advanced polymer materials is at the forefront of innovations in plastic part manufacturing, significantly enhancing performance while focusing on sustainability. These modern polymers incorporate unique properties like increased strength, flexibility, and resistance to extreme temperatures, allowing manufacturers to produce lighter and more durable components. This leads to improved product longevity and reduces the need for frequent replacements, ultimately lowering overall material consumption.

Furthermore, the emphasis on reducing waste in the manufacturing process is driving the adoption of recyclable and biodegradable materials. Innovations such as bio-based polymers and closed-loop recycling systems are becoming integral to the industry, enabling manufacturers to minimize their environmental footprint. By utilizing materials that can be reprocessed and reused, the industry not only conserves resources but also contributes to a circular economy, where plastic waste is significantly reduced and more products can be created from fewer raw materials. This shift not only meets growing consumer demands for eco-friendly products but also positions the manufacturing sector towards a more sustainable future.

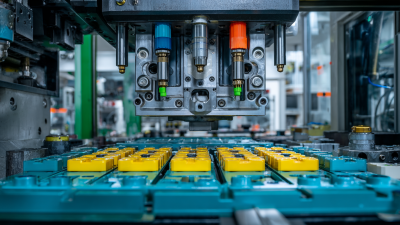

The integration of Internet of Things (IoT) and artificial intelligence (AI) is revolutionizing the plastic part manufacturing industry, paving the way for smart manufacturing. IoT devices facilitate real-time data collection from machinery and production lines, allowing manufacturers to monitor their processes closely. This data flow provides insights into machine performance, enabling predictive maintenance and minimizing downtime, thus enhancing overall operational efficiency.

AI plays a crucial role in analyzing the large volumes of data generated by IoT systems. By employing advanced algorithms, AI can identify patterns and trends that human operators might miss. This capability empowers manufacturers to make informed decisions quickly, optimize production schedules, and improve resource allocation. Additionally, AI can assist in quality control by enabling automated inspection processes, ensuring that only parts that meet specifications proceed through the production cycle. Together, IoT and AI create a smarter, more responsive manufacturing environment that is essential for the future of plastic part production.

The integration of automation into plastic manufacturing operations has become a critical strategy for cost reduction in the industry. According to a recent report by the McKinsey Global Institute, manufacturing firms that embrace automation can reduce operational costs by up to 30%. This shift is driven by advances in robotics and AI technologies that enable higher precision and efficiency in production processes. Automated systems not only streamline repetitive tasks but also significantly decrease labor costs, which are particularly crucial in regions facing high wage inflation.

Moreover, the rise of smart factories, enabled by the Industrial Internet of Things (IoT), is revolutionizing plastic part manufacturing. A report from Deloitte highlights that companies implementing IoT technologies in manufacturing could see productivity increases of 20-30%. By tapping into real-time data analytics, manufacturers can optimize their supply chain, reduce material waste, and enhance predictive maintenance, further driving down costs. As these innovations continue to evolve, the plastic manufacturing sector is poised for significant transformation, positioning automation as a cornerstone for achieving competitive advantage and sustainability.

880 W 9th Street

Upland, California 91786

884 W 9th Street

Upland, California 91786

886 W 9th Street

Upland, California 91786

884 W 9th Street

Upland, California 91786