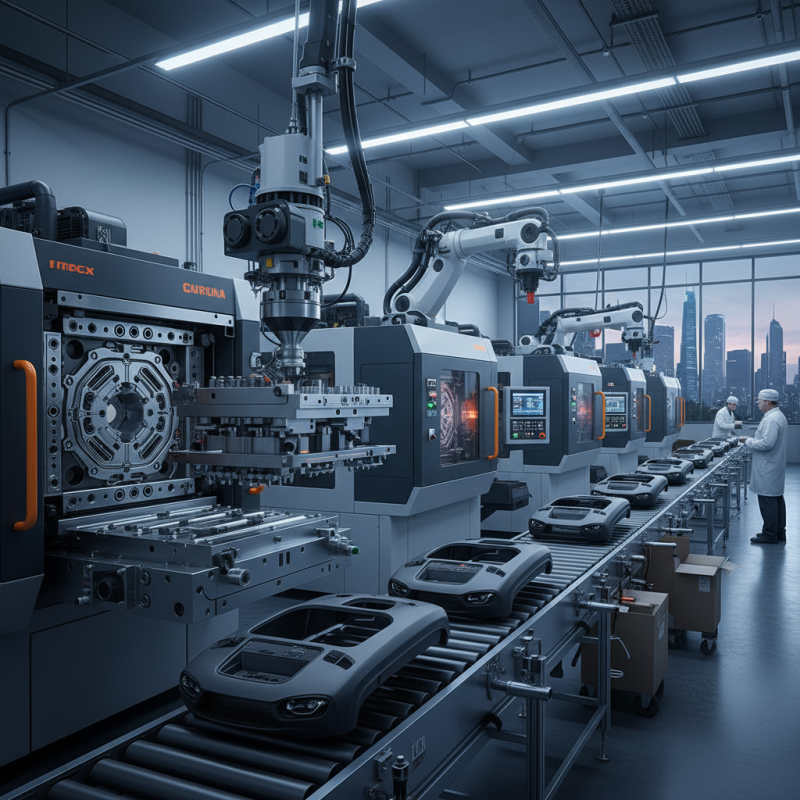

The injection molding mold plays a crucial role in achieving efficient production processes across various manufacturing sectors, particularly in the automotive and consumer goods industries. According to a recent report by MarketsandMarkets, the global injection molding market is expected to reach $335.25 billion by 2026, reflecting a compound annual growth rate (CAGR) of 5.4% from 2021 to 2026. This robust growth highlights the increasing reliance on injection molding technologies for mass production, where precision and efficiency are paramount.

Industry expert Dr. Emily Huang, a leading figure in polymer processing technology, states, "The efficiency of any injection molding process is largely contingent on the design and quality of the injection molding mold used." Her insights underline the significance of investing in high-quality molds that can withstand the rigors of production while ensuring dimensional accuracy and reduced cycle times. By utilizing advanced materials and innovative design techniques, manufacturers can enhance their production capabilities, minimize waste, and ultimately drive down costs.

As the demand for complex and high-performance components continues to rise, so does the necessity for high-quality injection molding molds. The ability to rapidly produce intricate parts with remarkable precision not only ensures competitive advantage but also supports sustainability efforts within the manufacturing landscape. Thus, understanding the pivotal role of injection molding molds is essential for any organization aiming to optimize its production processes and enhance overall operational efficiency.

Injection molding is a widely used manufacturing process essential for producing a variety of plastic components efficiently and cost-effectively. At the heart of this process lies the injection molding mold, a custom-designed tool that shapes each part with precision. According to a report from the Plastics Industry Association, injection molding accounts for more than 30% of the total plastics production in North America, emphasizing its significance in the industry.

The injection molding mold plays a critical role in ensuring high-quality production while minimizing waste and production time. Its design directly influences the cycle time, dimensional accuracy, and surface finish of the final product. A well-engineered mold can reduce cycle time by as much as 20-40%, enhancing overall productivity and carbon efficiency, as indicated by studies from the Society of Plastics Engineers. These molds are usually made from durable materials such as steel or aluminum, which can withstand high pressure and heat, ensuring longevity and reliability.

**Tips**: When investing in injection molding molds, consider the following: prioritize precision in the mold design to avoid post-processing costs; evaluate the total cost of ownership, which includes maintenance; and always opt for molds capable of quick color changes to improve flexibility in production runs. This strategic approach can enhance efficiency and responsiveness to market demands, thereby preserving competitive advantage in the manufacturing landscape.

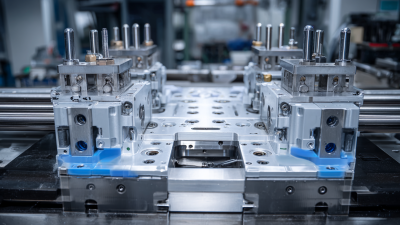

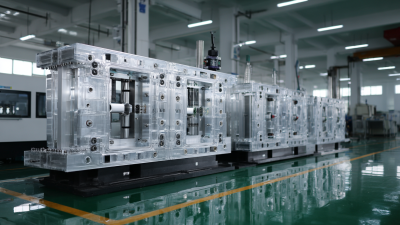

In the injection molding process, molds serve as the backbone of production efficiency. They are precisely engineered to create specific shapes and features of plastic components, ensuring consistency and quality across batches. The design of the mold dictates the final product's dimensions, surface finish, and overall integrity, making the mold itself an integral component in achieving high manufacturing standards. Molds are typically constructed from durable materials that can withstand the immense pressure and heat involved in the injection molding process, allowing for repeated use without sacrificing quality.

The role of molds extends beyond mere shape formation; they also influence cycle times and material usage. Well-designed molds facilitate faster cooling times and enable complex geometries to be formed with minimal waste. This efficiency not only reduces production costs but also enhances the speed at which products can be brought to market. Moreover, advancements in mold-making technology, such as the use of computer-aided design (CAD) and additive manufacturing, have further optimized the mold-making process, allowing for more intricate designs and quicker turnaround times. Hence, molds are not just tools; they are central to optimizing production processes in the injection molding industry.

| Mold Type | Material Used | Cycle Time (seconds) | Expected Lifespan (cycles) | Cost ($) |

|---|---|---|---|---|

| Cold Runner | Aluminum | 20 | 50,000 | 5,000 |

| Hot Runner | Steel | 15 | 1,000,000 | 20,000 |

| Two-Shot Mold | P20 Steel | 30 | 500,000 | 35,000 |

| Insert Mold | Aluminum | 25 | 100,000 | 10,000 |

| Stack Mold | NK80 Steel | 18 | 1,000,000 | 45,000 |

The efficiency and longevity of injection molding molds are heavily influenced by several key factors that directly affect production processes. One significant element is material selection; the right choice of steel or aluminum can dramatically alter both mold durability and the quality of produced parts. According to a report from the Society of Plastics Engineers, high-quality tool steel increases mold life by an estimated 30-50% compared to lower grade materials. This longevity translates into reduced downtime and lower production costs, reinforcing the importance of initial material investment.

Another crucial factor impacting mold efficiency is the design complexity. Advanced design techniques, such as conformal cooling channels, allow for better temperature control during the injection process, which ultimately enhances part quality and reduces cycle times. Research from the American Mold Builders Association indicates that proper thermal management can decrease cycle times by up to 20%, leading to significant gains in production throughput. Additionally, maintaining a rigorous preventive maintenance schedule ensures that molds operate effectively over time, minimizing wear and tear that can lead to costly repairs and delays. By considering these factors, manufacturers can optimize their production processes and maximize their return on investment in injection molding operations.

High-quality injection molding molds play a critical role in ensuring that production processes are not only efficient but also produce consistent and reliable results. One of the primary benefits is enhanced precision in manufacturing. Using well-designed molds minimizes the risk of defects in the final products, which leads to lower scrap rates and less rework. This precision translates to lower production costs over time, as manufacturers can operate at higher speeds and meet stringent quality standards without compromising on product integrity.

Another significant advantage of investing in high-quality molds is their durability and longevity. Molds that are crafted from top-grade materials are less likely to wear down or require frequent repairs. This durability means that production lines can run uninterrupted, contributing to higher overall productivity. Additionally, superior molds often come equipped with advanced features, such as better thermal control and cooling systems, which can further optimize cycle times and enhance energy efficiency during the manufacturing process. Thus, the benefits of utilizing high-quality injection molding molds extend beyond just immediate product quality; they also play a pivotal role in streamlining production operations and reducing costs in the long run.

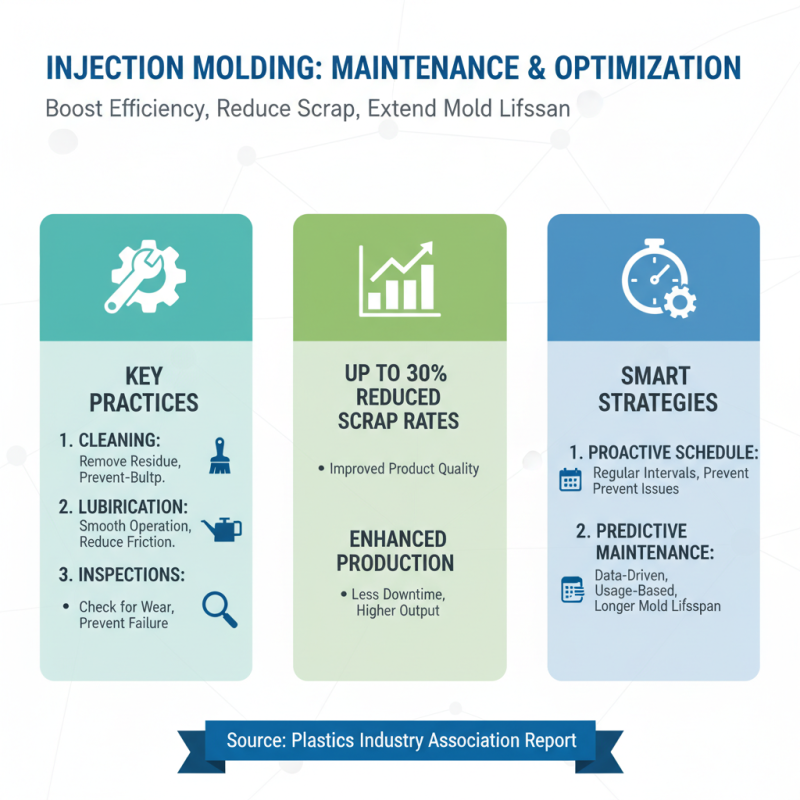

Maintaining and optimizing injection molding molds is crucial for maximizing production efficiency and product quality. According to a report by the Plastics Industry Association, mold maintenance can reduce scrap rates by up to 30%, significantly enhancing overall production efficiency. Regular maintenance practices, such as thorough cleaning, lubrication, and inspections, can prevent potential failures and ensure smooth operation. Mold wear can affect part dimensions and surface finishes; therefore, a proactive maintenance schedule is essential. Implementing a predictive maintenance strategy based on usage data can further enhance mold longevity, reducing unexpected downtimes and costs associated with production halts.

Additionally, optimizing molds involves not only maintaining their physical condition but also refining their design and cooling systems. Research shows that molds with improved cooling efficiency can reduce cycle times by up to 50%. This is achieved by employing advanced cooling techniques, such as conformal cooling channels, which allow for more uniform temperature distribution. Engineers should also focus on the selection of appropriate materials for the molds, as high-quality steels can withstand greater wear and thermal shock. By integrating these best practices into the production process, manufacturers can ensure that their injection molding operations remain competitive, sustainable, and responsive to market demands.

880 W 9th Street

Upland, California 91786

884 W 9th Street

Upland, California 91786

886 W 9th Street

Upland, California 91786

884 W 9th Street

Upland, California 91786