In recent years, the landscape of the manufacturing industry has transformed significantly, driven by advancements in technology and innovative practices. Injection mold makers have been at the forefront of this evolution, harnessing modern manufacturing techniques to enhance productivity and efficiency. According to a report by MarketsandMarkets, the global injection molding market is projected to reach $306.71 billion by 2024, growing at a CAGR of 3.6% during the forecast period. This growth highlights the critical role of injection mold makers in providing high-quality, precise designs that meet the increasing demand across various sectors, including automotive, consumer goods, and healthcare. As these manufacturers adopt cutting-edge technologies such as additive manufacturing, smart automation, and advanced materials, understanding the innovations in injection mold making becomes essential for industry stakeholders aiming to remain competitive in a rapidly evolving market.

The landscape of injection mold making is rapidly evolving, driven by the integration of innovative materials that enhance the efficiency and performance of manufacturing processes. One of the most significant advancements is the development of high-performance thermoplastics and thermosetting plastics, which offer greater strength, durability, and heat resistance compared to traditional materials. These advanced polymers not only improve the lifespan of molds but also allow for the production of more complex and intricate designs, catering to diverse industries ranging from automotive to consumer electronics.

Additionally, the emergence of composite materials is transforming the injection mold manufacturing sector. Composites, like carbon fiber and fiberglass reinforced plastics, provide superior mechanical properties while significantly reducing weight. This characteristic is particularly beneficial in applications where weight reduction is crucial without sacrificing performance. Furthermore, the use of bio-based materials is gaining traction, driven by sustainability concerns. These eco-friendly alternatives seek to reduce the carbon footprint of production processes while maintaining high-quality standards, paving the way for a more environmentally conscious approach to injection mold making.

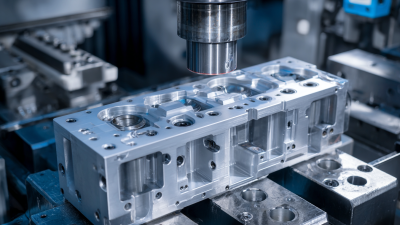

CNC machining has revolutionized the way mold makers create intricate and precise designs. Advanced technologies such as multi-axis machining and high-speed cutting allow for the rapid production of molds with complex geometries. By leveraging these capabilities, manufacturers can reduce lead times and enhance the accuracy of their mold components, ensuring a better fit and finish for the final products. Incorporating automation in CNC operations also streamlines processes, allowing mold makers to focus on refinement and innovation rather than tedious manual tasks.

**Tip:** When selecting CNC machines for mold making, consider those that offer adaptable tooling options. This flexibility can significantly speed up production times and reduce costs, especially when responding to varying project demands.

Moreover, integrating software solutions like CAD/CAM further optimizes the mold creation process. These programs enable precise modeling and simulation, allowing mold makers to anticipate potential issues during the manufacturing phase. This comprehensive approach not only improves efficiency but also enhances collaboration among teams, resulting in higher quality molds that meet exact specifications.

**Tip:** Invest in training for your team on the latest CAD/CAM technologies. A well-trained workforce can better leverage these tools, leading to innovative designs and improved production practices.

Automation has become a cornerstone in the evolution of injection mold manufacturing, significantly enhancing production efficiency. With advancements in robotics and artificial intelligence, modern mold makers can streamline their operations, reducing human error and increasing precision. Automated systems can now handle tasks such as mold design, material handling, and quality inspection, allowing manufacturers to produce higher volumes with consistent quality. This shift not only accelerates the production timeline but also maximizes resource utilization.

Furthermore, the integration of automation facilitates real-time monitoring and data analysis, enabling manufacturers to proactively manage their processes. By utilizing IoT (Internet of Things) devices, mold makers can gather critical operational data that lead to informed decision-making and predictive maintenance. This innovation minimizes downtime and enhances workflow, resulting in a more robust and agile manufacturing environment. As a result, companies that embrace these automated techniques are better positioned to respond to market demands and enhance their competitive edge in the injection mold industry.

Sustainable practices are becoming increasingly significant in the field of injection mold manufacturing, driven by both consumer demand and regulatory pressures. Modern manufacturers are integrating eco-friendly materials and processes that reduce waste and minimize the carbon footprint associated with traditional production methods. For instance, many companies are now exploring bio-based plastics and recycled materials as alternatives to conventional polymers, which not only helps in conserving resources but also appeals to environmentally conscious consumers.

Furthermore, innovations in technology are facilitating more sustainable approaches. Advanced manufacturing techniques, such as additive manufacturing and precision engineering, are improving efficiency and reducing material waste during the molding process. These methods allow for tighter tolerances and better resource management, enabling companies to produce high-quality molds with minimal environmental impact. By prioritizing sustainability, injection mold makers are not only enhancing their competitive edge but also contributing to a more sustainable future in the manufacturing sector.

The landscape of mold design and manufacturing is rapidly evolving, particularly with the rise of advanced design software. Emerging trends in this field are increasingly focused on integrating various semiconductor components—such as logic, memory, sensors, and RF—into cohesive modules. This strategic bundling not only enhances system performance but also significantly reduces power consumption. According to a recent industry report, the integration of these components can lead to improvements in operational efficiency of up to 30% and a reduction in energy usage by nearly 15%.

Modern software solutions are incorporating sophisticated simulation and modeling capabilities, allowing designers to visualize and optimize the mold development process much earlier in the production cycle. This shift is facilitating shorter lead times and reduced costs, with some manufacturers reporting decreases of around 25% in their overall production timelines. Additionally, the rise of collaborative design tools is enabling teams to work more effectively, which addresses the complexity of designing for multi-functional semiconductor modules. As these trends continue to unfold, the importance of adopting innovative design software is becoming paramount for companies looking to maintain a competitive edge in the advanced manufacturing sector.

880 W 9th Street

Upland, California 91786

884 W 9th Street

Upland, California 91786

886 W 9th Street

Upland, California 91786

884 W 9th Street

Upland, California 91786