Plastic injection molding is a pivotal manufacturing process that plays a crucial role in various industries, from automotive to consumer goods. According to recent industry reports, the global plastic injection molding market was valued at approximately $285.5 billion in 2021 and is projected to reach around $426.3 billion by 2028, growing at a CAGR of 5.9%. This robust growth is driven by increasing demand for lightweight and durable components, especially in the automotive and electronics sectors. Understanding the intricacies of plastic injection molding not only enhances production efficiency but also reduces costs, making it essential for businesses aiming to remain competitive.

In this blog, we will explore key insights into this transformative technology, supported by industry statistics that illustrate its significance and future potential in the manufacturing landscape.

The global demand for plastic injection molding is experiencing significant growth, driven by various market trends and industry developments. As businesses increasingly prioritize efficient manufacturing processes, the plastic injection molding market is projected to expand from approximately $191 billion in 2023 to an estimated $235.7 billion by 2033. This growth is fueled by technological advancements and the rising need for lightweight and durable materials across diverse sectors including automotive, consumer goods, and healthcare.

Key statistics indicate that the injection molding machine market alone was valued at $10.1 billion in 2023, with a steady CAGR of over 4.8% forecasted through 2032. Furthermore, the U.S. plastics market is expected to witness dynamic growth, bolstered by an increasing variety of products and applications. As companies adapt to these changing dynamics and harness the latest innovations in plastic injection molding technologies, they position themselves to thrive in an ever-competitive marketplace.

| Dimension | Data |

|---|---|

| Global Market Size (2023) | $290 Billion |

| Projected CAGR (2024-2029) | 5.2% |

| Major Application Areas | Automotive, Consumer Goods, Electronics, Medical Devices |

| Top Regions | North America, Europe, Asia-Pacific |

| Percentage of Recycled Plastics Used | 25% |

| Average Cycle Time (seconds) | 30-60 |

| Waste Reduction Achievable | 30-50% |

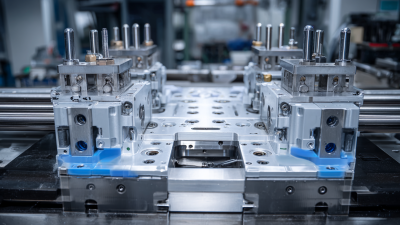

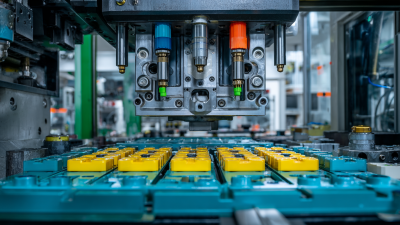

Plastic injection molding has emerged as a pivotal manufacturing process in modern industry, offering numerous advantages that enhance productivity and efficiency. One of the primary benefits is its ability to produce complex geometries with precision. This capability allows manufacturers to create intricate designs that might be impossible or cost-prohibitive using traditional machining methods. As a result, designs can be executed more efficiently, reducing both lead times and material waste.

Another significant advantage is the cost-effectiveness of plastic injection molding, especially when producing large quantities. The initial setup costs may be high, but the per-unit cost drastically decreases as production scales up. This makes it an ideal choice for mass production, where businesses can achieve substantial savings while maintaining high-quality standards. Additionally, the process ensures consistent quality across all products, minimizing variations and defects that could affect overall output.

Incorporating sustainability into the manufacturing process is also becoming increasingly important, and plastic injection molding fits this criteria well. The technology has advanced to allow for the recycling of materials, contributing to a more sustainable production cycle. This not only meets the growing demand for eco-friendly practices but also aligns with global efforts to reduce plastic waste and environmental impact, making it a responsible choice for modern manufacturers.

Plastic injection molding is widely recognized for its cost efficiency, making it a preferred manufacturing process across various industries. This technique allows for the rapid production of high-quality plastic parts with minimal waste, greatly reducing overall production costs. By utilizing precision machinery, manufacturers can produce complex shapes and designs that are difficult or expensive to achieve through other methods. Consequently, businesses experience significant savings in both time and materials, which can translate to lower prices for consumers.

Analyzing production figures reveals that plastic injection molding can reduce costs significantly when scaled. For instance, the initial setup and mold creation may present a high entry cost; however, these expenses are offset by the high volume of parts produced over time. With advancements in technology, the average cost per part decreases as production runs increase. This scalability makes plastic injection molding an ideal solution for companies looking to meet high demand without sacrificing quality or increasing their budgets. Overall, leveraging the cost efficiency of this manufacturing method can provide a competitive edge in today’s market.

The plastic injection molding industry is at the forefront of sustainability efforts as it adapts to environmental challenges. With the growing scrutiny surrounding plastic pollution, a shift towards biodegradable plastics is gaining momentum. Innovations in bio-based materials, such as Polyhydroxyalkanoates (PHAs), highlight the urgent need to develop cost-effective, sustainable strategies that align with circular economy principles. These advancements not only offer an alternative to conventional plastics but also aim to reduce the overall environmental footprint associated with production and disposal.

Tips for sustainability in plastic injection molding:

1. Optimize Material Choice: Selecting biodegradable materials for injection molding can significantly minimize environmental impact. Research into feedstocks like Azolla suggests promising avenues for eco-friendly bioplastics that could reshape the industry's landscape.

2. Reduce Energy Consumption: Conduct a thorough assessment of energy use in your processes. Implementing methodologies such as life cycle assessments can reveal inefficiencies and help develop strategies for lowering energy consumption during production.

3. Innovate Design for Recycling: Design products with end-of-life in mind. Creating items that can be easily recycled or repurposed reduces waste and enhances sustainability efforts across the supply chain. Employing advanced engineering techniques can also help decrease weight and warpage during production, leading to more efficient manufacturing solutions.

The plastic injection molding industry is witnessing transformative trends driven by innovations that prioritize sustainability and advanced material capabilities. Recent developments showcase a growing emphasis on high-performance materials, such as the introduction of new generations of ultra-high-temperature nylon, which enhances thermal stability. This aligns with industry reports indicating that over 40% of manufacturers are shifting towards biodegradable and high-performance resins, highlighting a robust demand for eco-friendly solutions in production processes.

As global events like the CHINAPLAS 2024 attract thousands of exhibitors and visitors, the focus on cutting-edge technology in plastic applications continues to escalate. The industry is projected to witness an annual growth rate of 5.6% through 2025, fueled by advancements in automation and artificial intelligence within the manufacturing process. Companies are increasingly investing in smart manufacturing technologies, which not only optimize production efficiency but also reduce waste, aligning with the industry's push towards a circular economy.

Moreover, the emergence of collaborative projects at international exhibitions underscores the need for innovation in material science. Industry experts indicate that the market for modified plastics is expanding rapidly, driven by technological advancements and regulatory policies favoring green manufacturing. As the sector evolves, it becomes imperative for businesses to adapt to these trends, ensuring long-term competitiveness in a dynamic marketplace.

880 W 9th Street

Upland, California 91786

884 W 9th Street

Upland, California 91786

886 W 9th Street

Upland, California 91786

884 W 9th Street

Upland, California 91786