Plastic injection molding is a critical manufacturing process that shapes a multitude of products across various industries, from automotive to consumer goods. According to a report by Grand View Research, the global plastic injection molding market is projected to reach $400 billion by 2027, reflecting the growing demand for precision and efficiency in production. Mastering this technique is not just essential for improving product quality but also for optimizing production time and cost.

Industry expert Dr. John Smith, a renowned figure in plastic manufacturing technologies, emphasizes the importance of best practices in this field, stating, “Efficiency in plastic injection molding comes down to understanding both the material properties and the machinery used. Innovating these elements can significantly enhance production effectiveness.” By implementing the right techniques and practices, businesses can harness the full potential of plastic injection molding, driving advancements that meet the evolving needs of the market. Through this detailed exploration, we aim to shed light on the key techniques and best practices that can elevate one’s proficiency in plastic injection molding, ensuring competitive advantage in an increasingly demanding landscape.

Plastic injection molding is a widely used manufacturing process that shapes molten plastic into a specific form using a mold. Understanding the basics of this process is crucial for anyone involved in the industry. The process begins with plastic granules being melted in a heated barrel and then injected under high pressure into a mold. Once the material cools and solidifies, the mold is opened to reveal the finished product. This method is known for its efficiency, precision, and ability to produce complex shapes at scale.

Tips: Always ensure that the mold is properly designed to minimize defects. Pay attention to the cooling times, as uneven cooling can lead to warping or shrinkage. Additionally, selecting the right type of plastic is essential for achieving desired product quality and functionality. Regular maintenance of the injection molding machine can also prevent downtime and enhance production reliability.

Another key aspect to master in plastic injection molding is the control of variables such as temperature, pressure, and injection speed. These factors can significantly impact the quality of the final product. Utilizing software for simulation can help optimize the process and predict potential issues before production begins. Keep in mind that thorough testing and validation should be conducted to ensure that the molded items meet quality standards and specifications.

| Technique | Description | Best Practices | Common Applications |

|---|---|---|---|

| Temperature Control | Maintaining optimal melt temperature for resin. | Use thermocouples for real-time monitoring. | Automotive parts, consumer goods. |

| Pressure Management | Controlling injection pressure to ensure material flow. | Adjust pressure based on mold design. | Electronic housings, plastic containers. |

| Cooling Phase Optimization | Efficient cooling to reduce cycle time. | Implement cooling channels in the mold design. | Complex shaped parts, thin-walled items. |

| Material Selection | Choosing the right resin based on application. | Understand mechanical and thermal properties of materials. | Medical devices, industrial components. |

| Mold Design Considerations | Creating molds that accommodate material flow. | Incorporate draft angles, radius edges. | Consumer products, packaging solutions. |

Successful plastic injection molding relies heavily on the right tools and equipment. Key components include injection molding machines, molds, and ancillary equipment. According to a report by Grand View Research, the global injection mold market was valued at approximately $20.7 billion in 2020 and is projected to expand at a CAGR of 5.9% from 2021 to 2028. This growth highlights the increasing demand for precision-engineered components across various industries, underscoring the critical need for high-quality equipment.

Injection molding machines, which are available in various configurations like hydraulic, electric, and hybrid, contribute significantly to the efficiency and effectiveness of the molding process. Selecting the appropriate machine is essential; for instance, electric machines offer advantages in speed and energy efficiency, while hydraulic machines are favored for larger products. Additionally, the choice of mold design—whether single-cavity or multi-cavity—will affect production rates and costs. Furthermore, auxiliary equipment such as temperature controllers, dryers, and conveyors play a vital role in ensuring optimal processing conditions and minimizing waste, thereby enhancing overall productivity.

Investing in the latest technology and equipment not only improves the quality of the molded parts but also reduces cycle times and operational costs. Reports indicate that manufacturers implementing advanced tools can enhance their production efficiency by up to 30%. By focusing on the essential equipment and tools, companies can better navigate the complexities of the injection molding process and achieve superior results in their production lines.

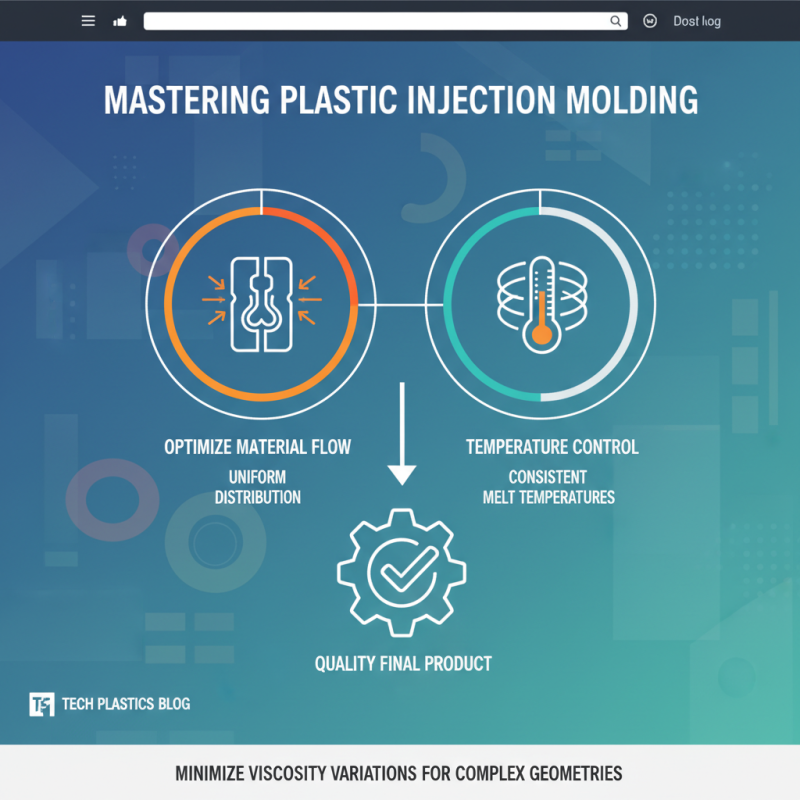

Mastering plastic injection molding requires a keen understanding of key techniques that optimize material flow and temperature control. Properly managing the flow of molten plastic into the mold is critical to ensure the final product meets quality standards. One effective method is to maintain consistent melt temperatures throughout the injection process. This minimizes viscosity variations and ensures uniform material distribution, which is vital for complex geometries.

**Tips:** To achieve optimal melt temperature, regularly calibrate your temperature sensors and monitor the heating elements. Implement a systematic approach to record and analyze temperature data during each run to identify any variations that may affect the quality of the final product.

Additionally, controlling the cooling phase is crucial to prevent warping and shrinkage. A well-designed cooling system will facilitate the efficient removal of heat from the molded parts without inducing internal stresses. Utilizing cooling channels strategically placed within the mold can drastically reduce cycle times and improve part stability.

**Tips:** Regularly inspect and clean cooling lines to prevent blockages. Use thermal imaging to identify hotspots and ensure even temperature distribution throughout the mold. This proactive approach will help you maintain high-quality standards while maximizing production efficiency.

Maintaining molding quality and consistency in plastic injection molding is crucial for producing high-quality parts that meet specific standards. One of the best practices is to establish a thorough quality control system. This system should include regular inspections of the molds and the parts produced. It helps identify any defects early on, allowing for timely repairs and adjustments. Monitoring the molding process parameters, such as temperature, pressure, and injection speed, is also essential to ensure they remain within prescribed limits.

Tip: Always keep detailed records of the molding process, as this data can highlight trends in quality issues and facilitate better troubleshooting over time.

Another important practice is to use high-quality materials consistently. Variations in material properties can lead to inconsistencies in the final product. Therefore, sourcing materials from reliable suppliers and adhering to strict specifications can considerably enhance product quality. Additionally, training staff to understand the significance of consistency in material handling and processing will fortify quality assurance throughout the production line.

Tip: Implement regular training sessions for the team to stay updated on best practices and emerging trends in plastic injection molding, ensuring everyone is aligned in their approach to maintaining quality.

In the realm of plastic injection molding, numerous challenges can arise throughout the production process. One common issue is material inconsistency, which can lead to defects in the final product. Variations in temperature, moisture levels, and material composition can all contribute to this problem. To combat material inconsistency, it's crucial to establish stringent supplier standards and conduct regular quality inspections on incoming materials.

Another significant challenge is achieving the desired part design and dimensions while maintaining efficiency. Mold design errors or improper machine settings can cause misalignment, leading to costly rework or scrap. To mitigate this, consider employing mold flow analysis software during the design phase to predict potential issues. Additionally, continuous monitoring of the injection parameters can help ensure that the mold fills correctly and the final dimensions meet specifications.

**Tips**: Regular training for machine operators on the latest techniques and best practices can significantly enhance the production process. Furthermore, establishing a routine maintenance schedule for equipment can prevent unexpected breakdowns and prolong machinery life. By prioritizing these proactive measures, manufacturers can simplify the injection molding process and improve overall quality.

880 W 9th Street

Upland, California 91786

884 W 9th Street

Upland, California 91786

886 W 9th Street

Upland, California 91786

884 W 9th Street

Upland, California 91786