Nail interlock is a crucial concept in the construction and manufacturing industries. It plays a significant role in enhancing the strength and durability of engineered products. According to industry reports, the demand for structural solutions using nail interlock technology has increased by 25% in the past five years. This growth highlights the importance of understanding how nail interlock works.

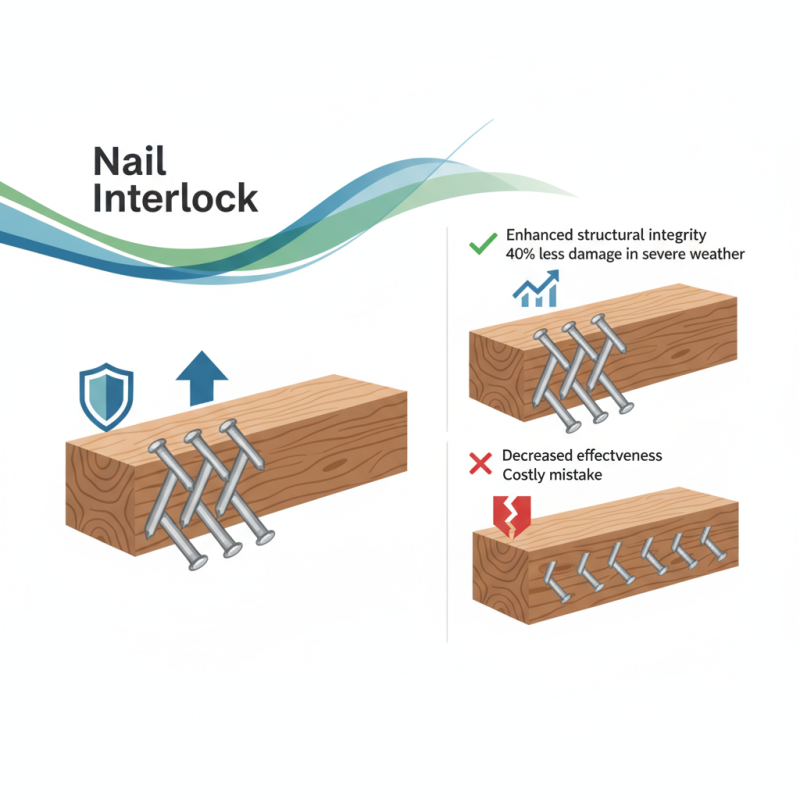

Nail interlock involves the interlocking of nails within wooden structures, creating a tighter bond. This method not only enhances structural integrity but also improves resistance to environmental factors. A recent study showed that projects utilizing nail interlock sustain 40% less damage during severe weather events. However, this technology is not without its challenges. Misalignment during installation can lead to decreased effectiveness.

Understanding nail interlock is vital for engineers and builders. Despite the technical advancements, the installation process requires careful consideration. Achieving the proper alignment often requires skill and experience. Striking the right balance between efficiency and precision can be daunting. A well-executed nail interlock can lead to long-lasting structures, while poor execution can be a costly mistake.

Nail interlock is an innovative technique used in construction and woodworking. It involves interlocking nails that bind two materials together securely. This method provides multiple benefits, such as enhanced stability and resistance to shear forces. According to industry reports, the use of nail interlock can increase structural integrity by up to 30%. This makes it a popular choice among builders and carpenters.

The design of nail interlock allows for better distribution of stress across the materials. This leads to reduced chances of failure at joints. In fact, a significant number of engineered wood products utilize this technique. Data suggests that up to 70% of modern timber structures benefit from advanced interlocking mechanisms. However, some practitioners argue that over-reliance on this technique can lead to complacency in traditional craftsmanship skills.

While nail interlock improves overall performance, errors can occur during installation. Misalignment or incorrect nail placement can weaken the connection. This highlights the importance of skilled labor and proper training. Continuous education in techniques is necessary to fully harness the potential of nail interlock. Understanding the balance between innovation and skill preservation remains essential in the industry.

Nail interlock is a fascinating technique used in various construction and woodworking applications. The core mechanism involves a system where nails fit together tightly, creating a strong joint. This method enhances stability, ensuring that components remain firmly in place. Each nail interlocks with the adjoining one, distributing stress evenly across the assembly.

The mechanics behind nail interlock hinge on precise alignment and the materials used. When properly executed, the interlocking design reduces sheer forces, making structures more resilient. However, achieving this requires skill and careful planning. Any misalignment can weaken the entire system, leading to potential failures. This aspect often demands a deeper understanding of material properties.

Consideration of environmental factors is also essential. Moisture, temperature changes, and load variations can impact how well interlocks perform. Reflection on these elements is crucial for longevity. Sometimes, the simplest designs yield the most robust results. Yet, many overlook the importance of details, risking structural integrity over time. Proper education on the nuances of nail interlock can greatly enhance its application in practical scenarios.

Nail interlocks are a popular choice in construction. They provide excellent structural support. The benefits of using nail interlock techniques are significant. These methods enhance stability and improve the overall strength of a structure.

One major advantage is the ease of assembly. Builders can quickly connect materials using interlocks. This speed can lead to reduced labor costs and faster project timelines. Additionally, nail interlocks create a seamless connection that can withstand various forces. This can lead to a more resilient building.

When utilizing nail interlocks, keep these tips in mind. Ensure that the angles are precise. Even a slight misalignment can weaken the joint. Check that the nails used are appropriate for the materials. Use galvanized or coated nails to prevent rusting. Every detail matters.

It’s crucial to be aware of potential challenges. Excessive use of interlocks may lead to overcomplication. Not all designs benefit from this technique. Always evaluate if it fits the project needs. Adjust techniques according to specific requirements for the best results.

Nail interlock technology finds significant application in various industries, particularly in construction and manufacturing. In construction, it ensures structural integrity by providing strong connections between different components. According to a report from the Construction Industry Institute, about 70% of structural failures relate to connection issues. This highlights the importance of reliable interlocking methods like nail interlock.

In manufacturing, nail interlock technology is used for assembling furniture and cabinetry. This method allows for easy, efficient assembly while maintaining a robust final product. A study by the Furniture Industry Association shows that products using interlock methods have a 30% lower return rate due to defects. This is a clear indicator of its reliability.

Tip: When considering nail interlock systems, evaluate the load-bearing requirements of your project. Ensure your design accounts for potential stress points. Testing prototypes is crucial for identifying weaknesses early on. Remember, not all interlocking methods suit every application. Each industry has its nuances, requiring tailored approaches.

Nail interlock is a popular joining method in construction and woodworking. It provides a strong connection through interlocking nails. However, how does it compare to other joining techniques? Each method has its pros and cons.

Traditional joinery relies on glue and mechanical fasteners. While effective, these methods may not offer the same strength as nail interlock. Glue requires curing time, which could delay projects. Mechanical fasteners can loosen over time, leading to wear and tear. Nail interlock, on the other hand, delivers immediate strength. It engages the material directly, creating a more stable joint.

But nail interlock isn't without its issues. Proper alignment is crucial. Misalignment can compromise the joint’s integrity. Unlike glue, once nails are in place, adjustments are limited. This inflexibility can lead to mistakes that are costly to fix. Overall, it's essential to weigh these factors against project needs when choosing a joining method.

| Joining Method | Description | Advantages | Disadvantages | Applications |

|---|---|---|---|---|

| Nail Interlock | A mechanical joining method using interlocking nails. | Strong joint, allows for expansion and contraction. | Installation can be labor-intensive. | Wood construction, furniture assembly. |

| Screw Join | Using screws to fasten two or more pieces together. | Easy to disassemble, reusable. | Can weaken the material around the hole. | Furniture, cabinetry, carpentry. |

| Glue Join | Adhesives are used to bond materials together. | Uniform load distribution, no visible fasteners. | Long curing time, less strength in extreme conditions. | Woodworking, cabinetry, musical instruments. |

| Dowel Join | Utilizing wooden dowels inserted between pieces. | Strong joints, aligns pieces accurately. | Requires precise drilling, not easily disassembled. | Furniture making, cabinetry. |

880 W 9th Street

Upland, California 91786

884 W 9th Street

Upland, California 91786

886 W 9th Street

Upland, California 91786

884 W 9th Street

Upland, California 91786