In today's competitive manufacturing landscape, companies are constantly seeking innovative methods to enhance production efficiency, and one such approach gaining widespread attention is metal injection molding. This advanced technique combines the versatility of plastic injection molding with the strength and durability of metal, enabling manufacturers to produce intricate geometries and complex designs with remarkable precision. By optimizing the processes involved in metal injection molding, businesses can significantly reduce cycle times, minimize waste, and improve the overall quality of their products.

This article will explore key strategies for optimizing production efficiency using metal injection molding, including material selection, process parameters, tooling design, and quality control measures. Emphasizing these strategies will not only enhance operational effectiveness but also lead to greater profitability in an increasingly demanding market.

Metal injection molding (MIM) is a transformative technology in the manufacturing sector, particularly for producing complex metal parts efficiently. Understanding the basics of MIM is crucial for manufacturers looking to enhance their production efficiency. The process begins with mixing fine metal powders with binding agents to create a feedstock that can be easily molded. This approach allows for the production of intricate geometries that are often difficult to achieve with traditional machining methods.

Once the parts are molded, they undergo a debinding process, where the binding materials are removed, followed by sintering, where the metal particles fuse together at high temperatures. This two-step process not only optimizes the production of small to medium-sized parts but also reduces material waste, making it a cost-effective alternative.

Manufacturers leveraging MIM can achieve high precision and uniformity in their products while significantly increasing their production rates. By understanding these foundational aspects, businesses can better implement MIM to optimize their operational efficiency and stay competitive within their industries.

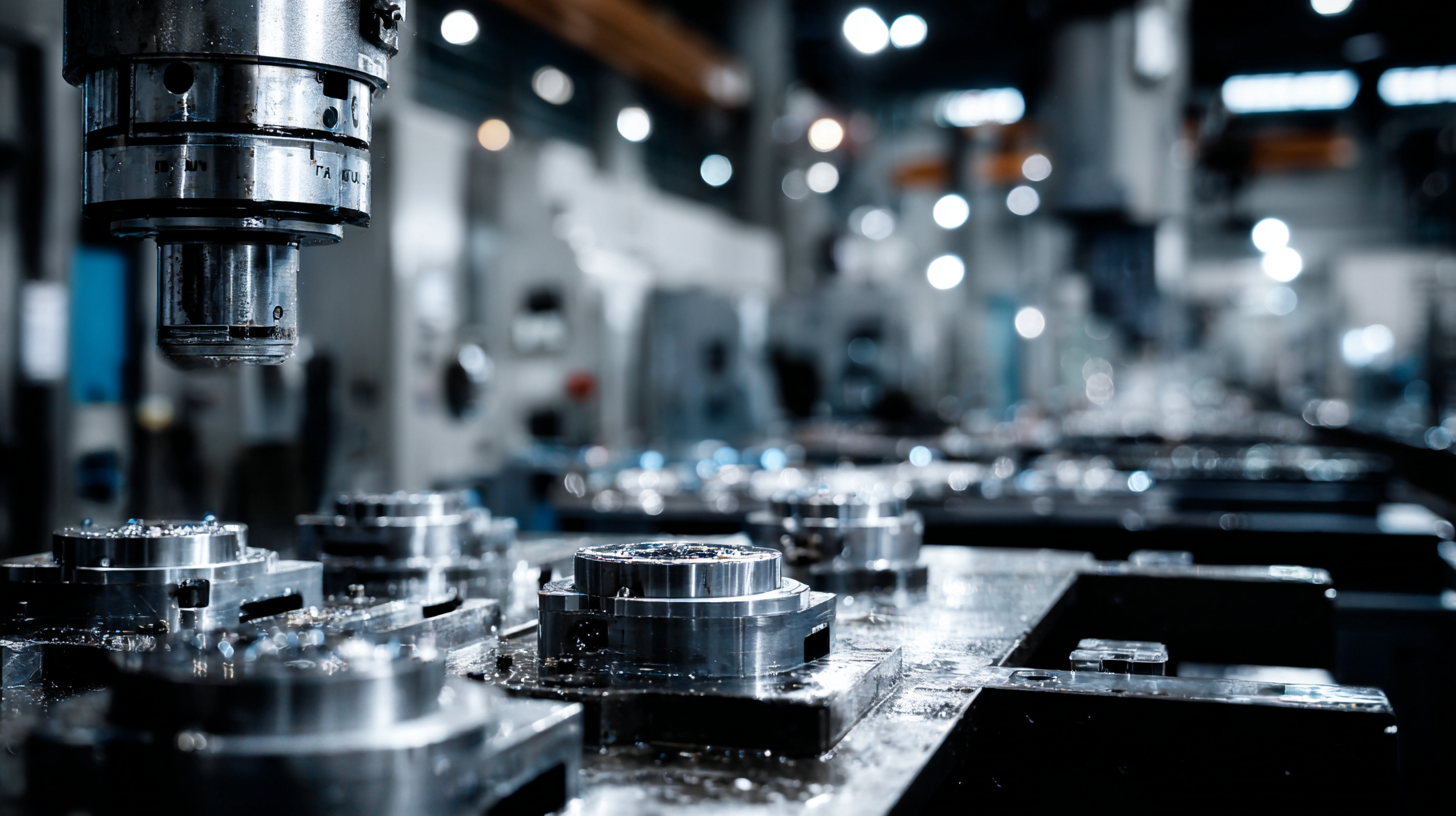

In the realm of metal injection molding (MIM), several key factors influence production speed that can significantly enhance overall production efficiency. With the global metal powder market projected to grow from $7.52 billion in 2023 to $13 billion by 2032, the demand for advanced manufacturing processes like MIM is on the rise. The efficiency of MIM is primarily dictated by the quality and uniformity of metal powders used, as well as the precision and capability of the molding equipment. Adequate powder characteristics, including particle size and flowability, are crucial in optimizing injection speed and mold filling, which can directly impact production turnaround times.

Moreover, the adoption of cutting-edge technologies, such as integrated casting machines, plays a critical role in enhancing MIM production efficiency. Manufacturers are increasingly investing in innovative systems that streamline the entire production process, reducing cycle times while maintaining high-quality output. For instance, as highlighted in recent trends, the focus on advanced magnesium alloy semi-solid injection molding techniques is reshaping manufacturing capabilities, presenting manufacturers with new opportunities to improve productivity and product quality. This commitment to innovation and efficiency in MIM processes will be pivotal as the industry continues to expand in response to rising global demand.

When it comes to optimizing production efficiency in metal injection molding (MIM), selecting the right materials is a critical factor that can significantly enhance output. According to a report by Grand View Research, the global metal injection molding market was valued at around $3.8 billion in 2021 and is expected to grow at a CAGR of 11.5% from 2022 to 2030. This growth highlights the increasing importance of material selection in MIM processes, as high-performance materials facilitate faster production cycles and improved part quality.

Choosing the appropriate feedstock, which typically consists of metal powders and binder systems, is paramount. Utilizing low-viscosity binders can help reduce cycle times, thus enabling higher throughput. A study from the Metal Powder Industries Federation (MPIF) indicates that using premium metal powders can enhance mechanical properties, resulting in parts that meet stringent industry standards while minimizing post-processing needs. Furthermore, aligning material properties with specific application requirements, such as corrosion resistance and tensile strength, ensures that produced components consistently meet customer expectations and regulatory guidelines, ultimately maximizing production output.

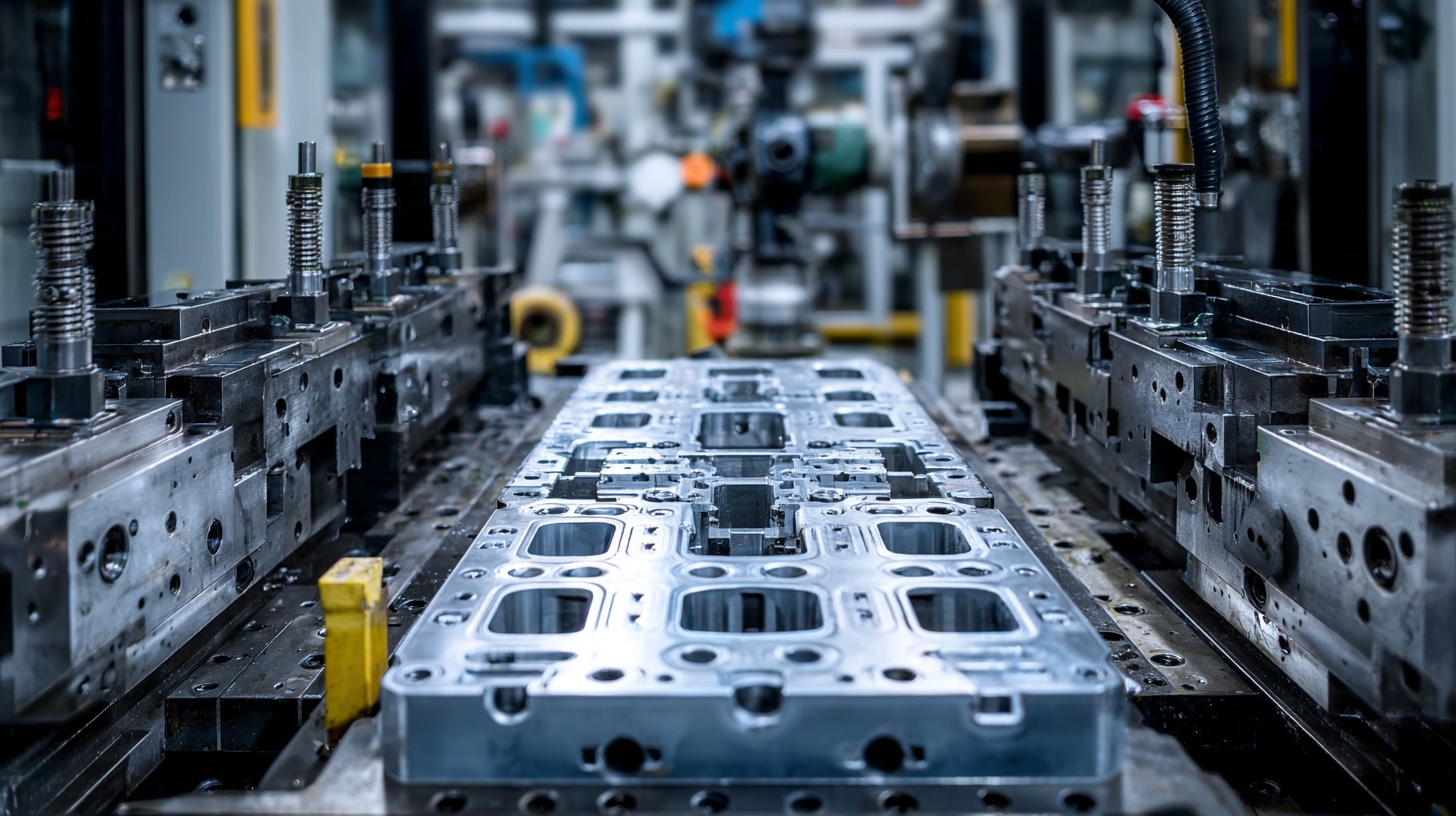

Metal Injection Molding (MIM) is a revolutionary process that combines the forming capabilities of plastic injection molding with the material properties of metal. To streamline the molding process and reduce waste, companies can implement several techniques. One effective approach is to optimize the feedstock formulation. By carefully selecting and controlling the powder and binder composition, businesses can ensure more consistent flow and improved packing density, which enhances overall quality and reduces scrap rates.

Tips: Regularly evaluate your feedstock suppliers to ensure you are using high-quality materials that meet your specific needs. Moreover, consider employing real-time monitoring systems during the injection process to quickly identify any variations in pressure or temperature, which can lead to defects and waste.

Another critical technique is to focus on the design for manufacturability (DFM). Designing parts with MIM-specific considerations, such as avoiding deep channels or overly complex geometries, can significantly improve the success rate of molding cycles. Simplifying designs not only reduces the risk of production errors but also minimizes the time and resources needed for tooling adjustments.

Tips: Collaborate with your engineering team early in the design phase and leverage simulation tools to visualize and analyze the flow of material, optimizing for efficiency before the actual production begins.

In the realm of metal injection molding (MIM), post-production steps play a crucial role in enhancing overall efficiency. Once the primary molding is done, it's essential to meticulously manage processes such as debinding and sintering. Debinding, which removes the binder material, must be carefully controlled to prevent defects in the final product. Optimal temperature and time settings during this stage ensure that the metal parts retain their integrity, leading to reduced defects and rework.

Moreover, the sintering process significantly influences the density and mechanical properties of the molded parts. By optimizing sintering parameters—such as temperature ramp rates, atmosphere control, and dwell times—manufacturers can produce parts that meet stringent performance standards. Advanced monitoring techniques, including real-time data analysis and process automation, can improve precision and reduce variability during these steps. Ultimately, a focus on refining these post-production processes not only boosts efficiency but also enhances product quality, paving the way for greater competitiveness in the market.

880 W 9th Street

Upland, California 91786

884 W 9th Street

Upland, California 91786

886 W 9th Street

Upland, California 91786

884 W 9th Street

Upland, California 91786