In the evolving world of manufacturing, plastic mold makers are at the forefront of innovation, driving significant transformations across industries. According to a recent report by Grand View Research, the global plastic injection molding market is projected to reach USD 440.78 billion by 2026, demonstrating a compound annual growth rate (CAGR) of 5.0%. This growth underscores the increasing demand for precise and efficient molding technologies. Plastic mold makers are not only enhancing the quality and speed of production but also integrating advanced technologies such as automation and digitalization into their processes. With an ever-pressing need for sustainability and waste reduction, these professionals are reshaping the manufacturing landscape, creating innovative solutions that meet modern market demands and set new standards for efficiency and environmental responsibility.

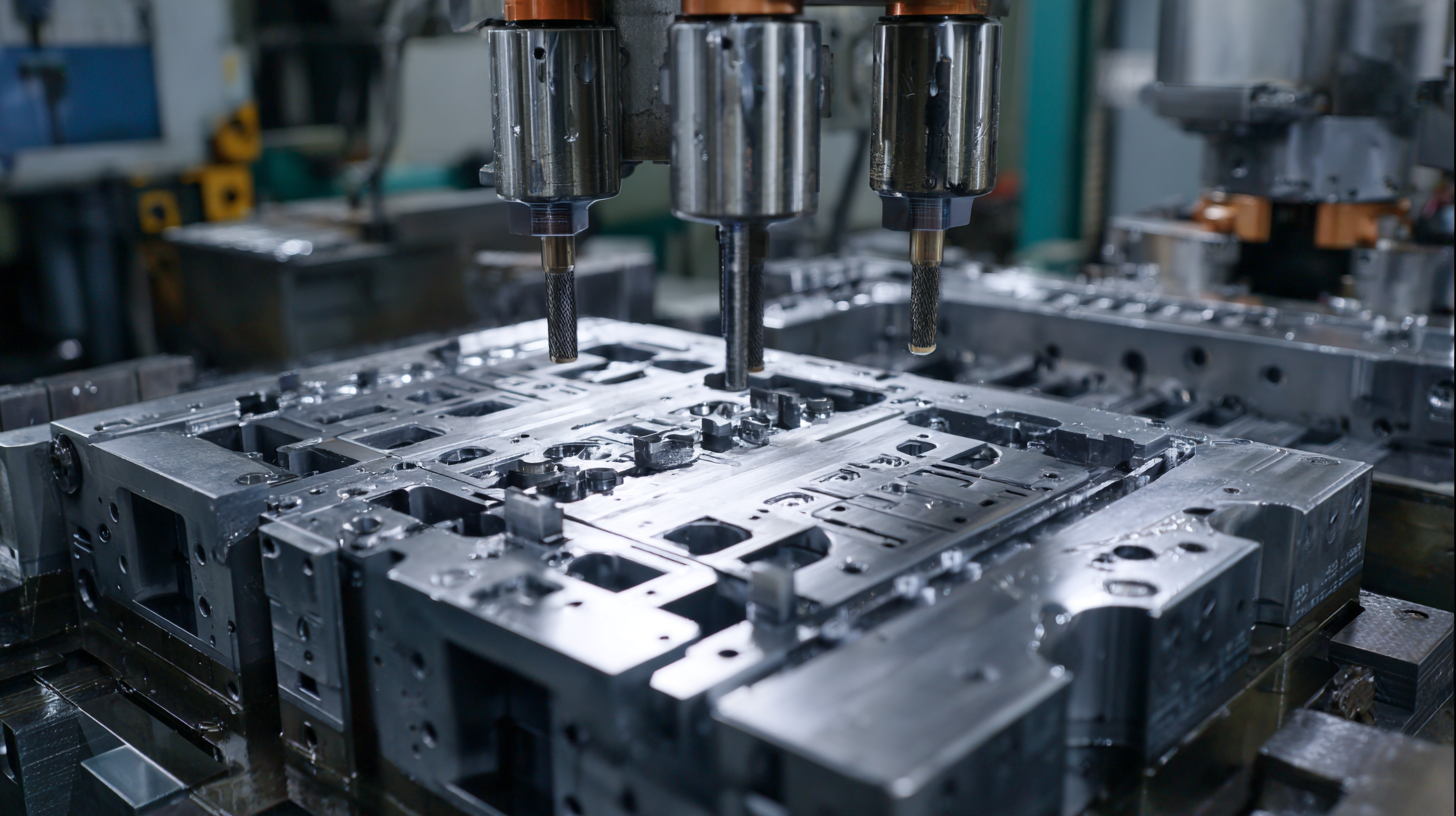

The landscape of plastic mold manufacturing is undergoing a significant transformation, propelled by advanced technologies that enhance efficiency and precision. According to a report by Grand View Research, the global plastic injection molding market size is expected to reach USD 400 billion by 2025, driven by increasing demand across various industries including automotive, consumer goods, and medical devices. This growth underscores the necessity for mold makers to adopt cutting-edge technologies such as 3D printing, computer-aided design (CAD), and artificial intelligence (AI) to remain competitive.

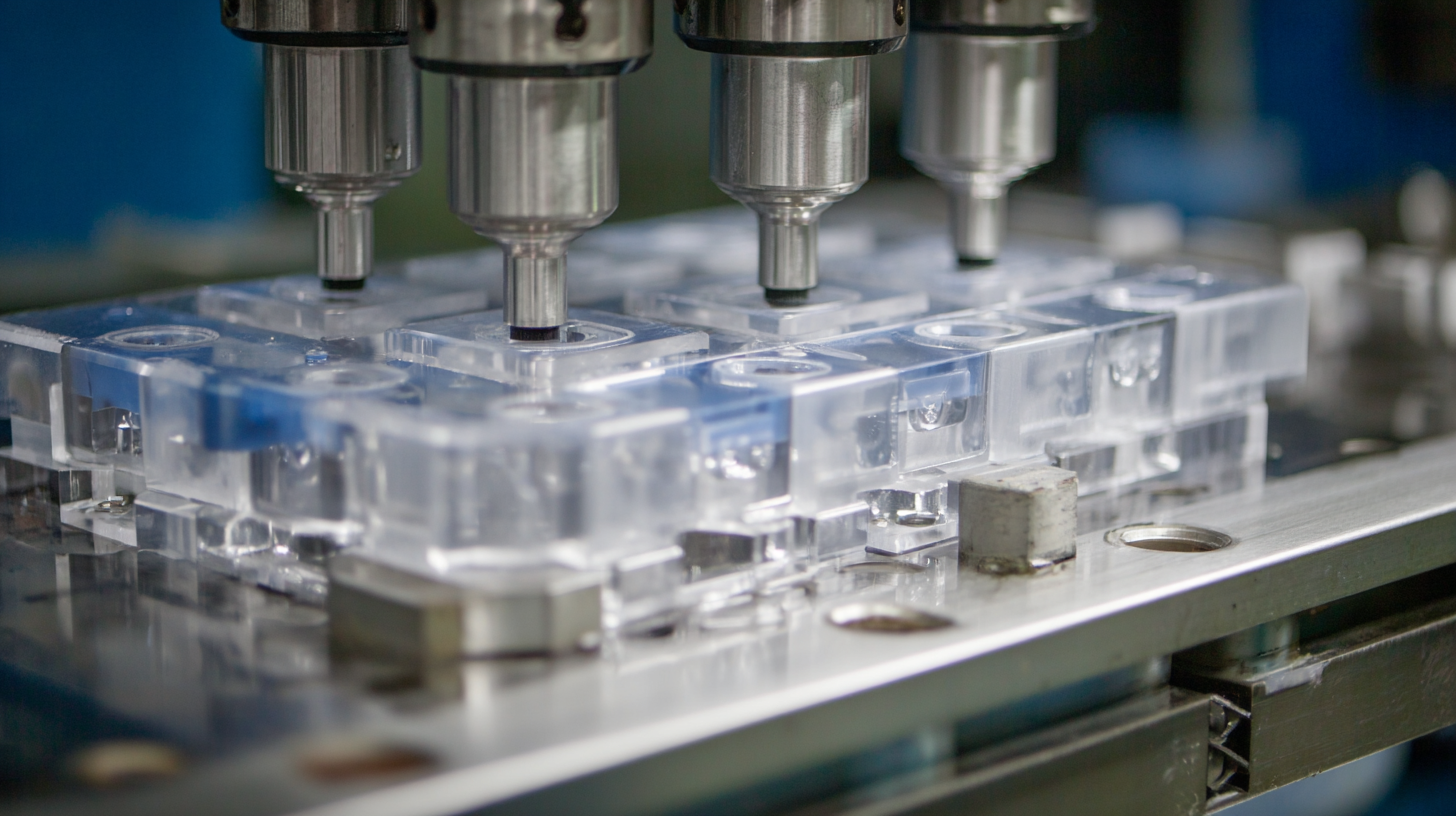

One of the most notable advancements is the integration of additive manufacturing techniques into mold making. By utilizing 3D printing, manufacturers can create complex mold geometries that would be impossible or prohibitively expensive to achieve using traditional methods. A recent study from the American Society of Plastic Engineers highlights that incorporating 3D printed molds can reduce production costs by up to 30% and accelerate the prototyping phase by 50%. Furthermore, AI-driven analytics are enhancing predictive maintenance and quality control, ensuring that molds are not only produced faster but with increased reliability. As these technologies continue to evolve, they are set to redefine the efficiency and capability of plastic mold manufacturing.

In the rapidly evolving manufacturing landscape, plastic mold makers play a pivotal role in enhancing production efficiency and unlocking innovation. One of the key strategies they employ is the integration of advanced technologies such as 3D printing and computer-aided design (CAD). According to a report from the American Society for Quality, companies that leverage additive manufacturing technologies have reported a 20% reduction in lead times for mold creation. This acceleration not only streamlines the prototyping process but also significantly decreases costs associated with traditional methods.

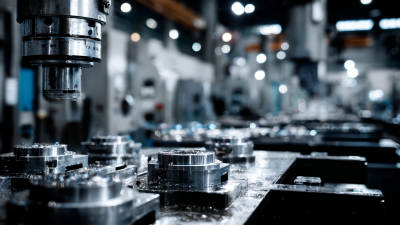

Moreover, the use of data analytics and machine learning in mold design is transforming how manufacturers operate. A study by MarketsandMarkets forecasts that the global market for smart manufacturing will reach $520 billion by 2025, largely driven by innovations in mold making. By utilizing predictive maintenance and performance analytics, mold makers can identify potential failures before they occur, reducing downtime and enhancing overall productivity. These strategies are essential for manufacturers looking to stay competitive in a marketplace that increasingly demands both speed and precision.

The manufacturing landscape is undergoing a profound transformation as mold makers embrace sustainable practices to meet the growing demand for eco-friendly solutions. By utilizing recycled materials and incorporating energy-efficient technologies into their processes, these innovators are not only reducing waste but also minimizing their carbon footprints. This shift towards sustainability reflects a broader commitment within the industry to prioritize environmental responsibility while maintaining high-quality production standards.

Moreover, the integration of sustainable practices enables mold makers to drive innovation by exploring new materials and designs that align with ecological principles. For instance, bioplastics and biodegradable materials are gaining traction, allowing manufacturers to create products that are both functional and environmentally friendly. As customers increasingly seek out companies that demonstrate a commitment to sustainability, mold makers positioned at the forefront of these changes are likely to gain a competitive edge, redefining the future of manufacturing in the process.

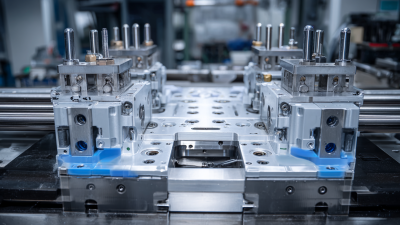

Collaboration between designers and mold makers is revolutionizing the manufacturing landscape, paving the way for innovative products that meet the ever-evolving demands of consumers. This partnership encourages a seamless exchange of ideas, allowing designers to convey their visions while mold makers apply their technical expertise to turn those visions into reality. By working together from the onset of the product development process, both parties can identify potential challenges and opportunities, ensuring that the final product is not only functional but also visually appealing.

Tips: To maximize the effectiveness of collaboration, establish clear communication channels from the beginning. Regular check-ins can help both designers and mold makers stay aligned on project goals and timelines. Additionally, utilizing collaborative design software can streamline the process, allowing for immediate feedback and alterations.

Emphasizing a culture of innovation is also crucial. When designers feel empowered to present bold ideas and mold makers are encouraged to experiment with new techniques, groundbreaking products can emerge. This symbiotic relationship fosters an environment where creativity and technical skills intertwine, ultimately leading to enhanced manufacturing capabilities and a competitive edge in the market.

The plastic mold industry is undergoing a significant transformation, driven by advancements in technology and innovative practices. Case studies reveal that companies implementing state-of-the-art additive manufacturing techniques have reduced production times by up to 50%. For instance, a leading mold maker in North America reported a 30% increase in efficiency after integrating 3D printing into their workflow, enabling rapid prototyping and design iterations. This not only streamlines the production process but also allows for more complex and intricate designs that were previously unattainable with traditional molding methods.

Additionally, a recent report by MarketsandMarkets forecasts the global plastic mold market to reach USD 12.9 billion by 2026, with a compound annual growth rate (CAGR) of 4.7%. This growth is largely attributed to the rising demand for lightweight materials in the automotive and electronics industries. Successful transformations in the plastic mold sector involve a focus on sustainability, with companies adopting eco-friendly materials and energy-efficient processes. One case highlights a mold manufacturer that reduced material waste by 40% through the implementation of smart technologies and recycling initiatives, showcasing the industry's commitment to both innovation and environmental responsibility.

| Transformation Area | Description | Impact | Case Study Example |

|---|---|---|---|

| Automation | Implementation of robotics to enhance precision and speed. | Increased production efficiency by 30%. | Robotic Arm Integration |

| 3D Printing | Utilization of additive manufacturing for mold prototypes. | Reduced prototyping time by 50%. | Rapid Prototyping Techniques |

| Material Innovation | Development and usage of advanced polymer blends. | Enhanced product durability and flexibility. | High-Performance Polymer Applications |

| Sustainable Practices | Adoption of eco-friendly materials and recycling processes. | Decreased waste output by 40%. | Sustainable Mold Manufacturing |

| Digital Transformation | Implementation of IoT for real-time monitoring. | Improved operational visibility and decision-making. | Smart Factory Solutions |

880 W 9th Street

Upland, California 91786

884 W 9th Street

Upland, California 91786

886 W 9th Street

Upland, California 91786

884 W 9th Street

Upland, California 91786