In the rapidly evolving landscape of global manufacturing, precision injection molding has emerged as a cornerstone of success across various industries. This advanced manufacturing technique not only enhances the accuracy and consistency of produced components but also enables businesses to meet the increasing demand for high-quality products in a cost-effective manner. As companies strive to remain competitive, embracing precision injection molding offers distinct advantages, such as reduced material waste, faster production times, and the ability to create complex geometries with unparalleled precision. In this blog, we will explore essential tips and best practices for leveraging precision injection molding, helping manufacturers maximize their operational efficiency and drive innovation in their product offerings. Discover how this technology can transform your production processes and solidify your position in the global market.

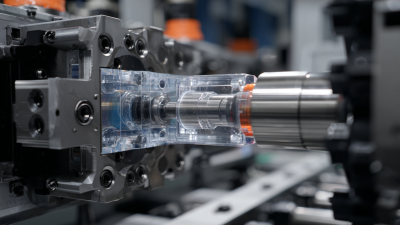

Precision injection molding has become a cornerstone of modern manufacturing, enabling companies to produce high-quality components with remarkable efficiency. This advanced technique allows for the creation of intricate designs and tight tolerances that are crucial in industries such as automotive, aerospace, and consumer electronics. By employing automated processes and state-of-the-art machinery, manufacturers can reduce material waste and enhance production speed, ultimately leading to significant cost savings.

The role of precision injection molding in meeting the ever-evolving demands of the market cannot be overstated. As manufacturers strive to develop lighter, stronger, and more complex products, precision injection molding provides the flexibility and scalability needed to innovate. This method not only supports rapid prototyping but also facilitates mass production, ensuring that businesses can keep pace with consumer preferences and technological advancements. In today’s competitive landscape, leveraging precision injection molding is essential for achieving operational excellence and maintaining a strong market presence.

Precision injection molding has emerged as a cornerstone of modern manufacturing, offering key advantages that go beyond mere production efficiency. One of the most significant benefits is its unparalleled accuracy in creating complex geometries with tight tolerances. This level of precision enables manufacturers to produce components that fit seamlessly with other parts, reducing the need for extensive post-processing and minimizing waste.

In an era where customization is king, the ability to deliver high-quality, precise parts quickly can set a company apart from its competitors.

Additionally, precision injection molding supports a broader range of materials, including advanced polymers that enhance product performance. With this capability, manufacturers can develop products that are not only lightweight but also strong and durable. This versatility allows businesses to innovate more freely, leading to unique design possibilities that can capture market share.

As industries demand shorter lead times and higher quality standards, precision injection molding positions companies to meet these challenges head-on, ensuring they maintain a competitive edge in a rapidly evolving global landscape.

The global injection molding market is poised for steady growth, yet it faces a myriad of challenges as it integrates more deeply into international manufacturing. As competition intensifies, manufacturers must navigate issues such as fluctuating raw material costs and increasing demand for faster production cycles. These pressures undermine the traditional practices of precision injection molding, necessitating innovative approaches to maintain competitiveness.

One standout strategy has emerged from AFT-Hungary, which effectively utilizes Metal Injection Molding (MIM) to address these challenges. By diversifying applications and enhancing material capabilities, they are not only meeting current market demands but also driving innovation within the sector. Meanwhile, companies like First Mold are optimizing their processes to reduce lead times significantly. Such operational improvements are crucial, especially in markets where speed and efficiency can dictate success.

This dynamic environment exemplifies the need for manufacturers to adapt and innovate continuously in response to the changing global landscape.

Precision injection molding has become a cornerstone of modern manufacturing, driven by innovations that enhance efficiency and quality. One significant advancement is the integration of advanced automation technologies. Automated systems not only speed up the production process but also minimize human error, resulting in consistent, high-quality outputs. This consistency is crucial for industries such as automotive and medical devices, where precision is paramount. Furthermore, the use of robotics within the molding process allows for intricate designs to be executed flawlessly, meeting the growing demand for complex components.

Another game-changing innovation is the development of smart materials and adaptive molding techniques. These materials exhibit properties that can change based on environmental conditions, which opens new avenues for product design and functionality. Additionally, adaptive molding allows for real-time adjustments during the manufacturing process, reducing waste and energy consumption. By leveraging such innovations, manufacturers can not only produce more efficiently but also respond quickly to market changes and consumer demands, thereby securing a competitive edge in the global market. These advancements in precision injection molding are transforming how industries operate, paving the way for sustainable and successful manufacturing practices.

| Dimension | Value |

|---|---|

| Cycle Time (seconds) | 25 |

| Material Waste (%) | 2 |

| Injection Accuracy (mm) | 0.01 |

| Energy Consumption (kWh) | 0.5 |

| Production Rate (units/hour) | 144 |

| Machine Utilization (%) | 85 |

| Quality Defect Rate (%) | 0.5 |

| Lead Time (days) | 10 |

Precision injection molding plays a critical role in achieving efficiency and quality in global manufacturing. Implementing effective strategies for precision injection molding can significantly enhance product consistency and reduce material waste. According to a 2021 report by MarketsandMarkets, the precision injection molding market is projected to reach $418.3 billion by 2026, indicating a compound annual growth rate (CAGR) of 5.9%. This rapid growth highlights the need for manufacturers to adopt best practices in their injection molding processes.

One of the key best practices is investing in advanced technology, such as automated systems and process monitoring tools, which can substantially improve operational efficiency. For instance, a study by the American Society of Mechanical Engineers revealed that automation can reduce production costs by up to 30%. Additionally, maintaining strict quality control standards throughout the manufacturing process is essential. Implementing statistical process control (SPC) methodologies can help manufacturers identify variations in production and rectify them promptly, ensuring that the final products meet stringent specifications. By prioritizing these strategies, organizations can not only enhance their manufacturing success but also solidify their competitive edge in the global market.

880 W 9th Street

Upland, California 91786

884 W 9th Street

Upland, California 91786

886 W 9th Street

Upland, California 91786

884 W 9th Street

Upland, California 91786