The landscape of plastic part manufacturing has undergone remarkable transformation in recent years, driven by innovative technologies and evolving market demands. According to a recent report by Smithers, the global plastic market is projected to reach $1 trillion by 2024, with plastic part manufacturing accounting for a significant share of this growth. This upward trend is reflective of an industry that is not only expanding but also becoming increasingly sophisticated, integrating advanced methods such as 3D printing, automation, and sustainable materials into production processes.

Industry expert Dr. Emily Carter, a leading figure in plastic part manufacturing research, emphasizes the critical role of innovation in this sector: "To thrive in the changing landscape of plastic part manufacturing, companies must embrace sustainable practices and leverage new technologies that enhance efficiency and reduce waste." Her insights underscore the importance of adapting to consumer expectations and regulatory pressures that favor eco-friendly practices.

As we delve into the top ten trends reshaping plastic part manufacturing in 2023, it becomes evident that the convergence of technology and sustainability is not merely a trend but a necessity for future competitiveness. From advancements in bioplastics to the adoption of smart manufacturing practices, the path forward is illuminated by a commitment to reinventing the traditional paradigms of production.

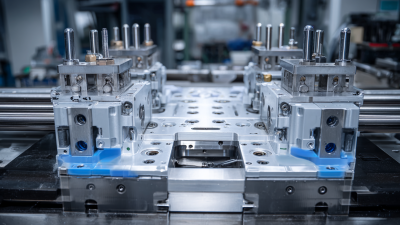

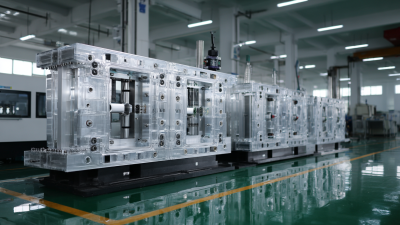

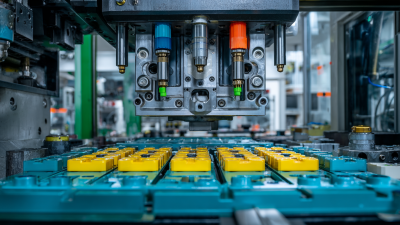

The plastic part manufacturing industry is experiencing a remarkable transformation, driven by emerging technologies that are shaping its future. Innovations such as 3D printing and automation are not only enhancing production efficiency but also enabling the creation of complex designs that were previously unimaginable. These advanced techniques allow manufacturers to reduce waste, lower costs, and respond more rapidly to market demands, fundamentally changing how products are designed and produced.

**Tips for Adapting to New Technologies:** Embrace digital tools that streamline production processes. Invest in training programs for your workforce to ensure they are equipped to handle new technologies. Collaborate with technology providers to stay updated on the latest trends and integrate them into your production lines effectively.

Moreover, sustainability is becoming a pivotal focus within the industry. Utilizing biodegradable materials and developing recycling initiatives can significantly impact a company’s environmental footprint. Companies that prioritize sustainable practices not only comply with regulatory demands but also enhance their brand image and appeal to environmentally-conscious consumers.

**Tips for Sustainable Practices:** Start by assessing your current material usage and identify sustainable alternatives. Implement a recycling program within your facility to minimize waste. Foster a culture of sustainability among your employees by educating them on the importance of eco-friendly practices in manufacturing.

Sustainable practices are becoming a cornerstone of innovation in the plastic manufacturing sector, driven by increasing environmental awareness and the urgency to reduce ecological footprints. Companies are exploring eco-friendly materials, such as edible bioplastics, developed through collaborative educational initiatives. This approach not only showcases creativity but also highlights the potential for transforming waste into valuable resources, facilitating a circular economy.

Events like the recent trade expos serve as crucial platforms for industry leaders to share their sustainable innovations and commitments. Companies are increasingly focusing on integrating technology to enhance their sustainability efforts, aiming for significant reductions in carbon emissions and resource consumption. As the sustainable shoe market indicates a promising growth trajectory, the broader implications for the plastic sector are clear: innovation in sustainable practices is essential for capturing market opportunities and meeting consumer demand for environmentally responsible products.

The U.S. plumbing fixtures and fittings market is poised for significant growth, driven by increased construction activity, advancements in water efficiency technologies, and a rising demand for modern bathroom and kitchen fixtures. As urbanization accelerates globally, alongside trends in renovation and sustainability, the market is projected to expand robustly. The market size for residential toilet tank accessories is expected to grow from $250 million in 2022 to $380 million by 2030, reflecting a compound annual growth rate (CAGR) of 6.5% from 2024 to 2030.

In the broader context, the global engineering plastics market, valued at $120.89 billion in 2023, is anticipated to reach $126.58 billion by 2031, growing at a CAGR of 5.22% during the forecast period. Similarly, the global injection molded plastics market is set to expand from $403.85 billion in 2024 to $561.58 billion by 2032, with a CAGR of 4.2%. These trends underscore an increasing reliance on innovative materials and production techniques within the plastic parts industry, paving the way for new opportunities and advancements.

The plastic manufacturing industry is experiencing a seismic shift, driven by a handful of key players who are redefining conventional practices with innovative strategies. Companies such as BASF and Dow Chemical are leveraging cutting-edge technologies like artificial intelligence and machine learning to optimize production processes. These advanced systems enhance efficiency, reduce waste, and improve the material quality of plastic parts, setting new industry standards and reducing environmental footprints.

In addition to technological advancements, collaboration is emerging as a vital strategy among top manufacturers. Partnerships between companies, research institutions, and startups are fostering the development of sustainable materials and recycling processes. For instance, companies like Covestro are actively investing in bio-based polymers and closed-loop systems, which not only meet regulatory demands for sustainability but also cater to an increasingly eco-conscious market. This collective shift towards innovation and sustainability is not only transforming the operational landscape but also positioning these manufacturers as pioneers in a rapidly evolving global market.

Collaborative efforts and

industry partnerships have become critical in enhancing

production efficiency within the plastic part manufacturing sector. As companies seek to innovate and respond

to growing demand, collaborations are being forged to leverage advanced technologies such as

AI and automation. For instance, partnerships between technology leaders and manufacturers have led to the

development of smart, sustainable manufacturing processes,

streamlining production and reducing waste.

Moreover, the rise of global innovation networks illustrates the importance of

cross-industry collaboration. By embracing open

communication and cooperative relationships, companies can tap into shared expertise and resources, driving

advancements in production techniques and reducing operational costs. As seen in various sectors like

semiconductors and healthcare,

collective intelligence is redefining manufacturing paradigms, paving the way for more efficient and

sustainable practices in the evolving landscape of

plastic part production.

880 W 9th Street

Upland, California 91786

884 W 9th Street

Upland, California 91786

886 W 9th Street

Upland, California 91786

884 W 9th Street

Upland, California 91786