In recent years, the manufacturing landscape has undergone transformative changes, driven by technological advancements and evolving market demands. One area that has seen significant progress is plastic injection molding, a critical process in producing high-precision plastic parts for various industries. According to a report by Grand View Research, the global injection molding market is projected to reach approximately $400 billion by 2025, growing at a compound annual growth rate (CAGR) of over 5%. This surge underscores the integral role of plastic injection molding in innovative manufacturing solutions, as businesses seek to enhance efficiency, reduce costs, and meet environmental standards.

The trends shaping the future of plastic injection molding are reflective of broader shifts towards sustainability, automation, and smart manufacturing. As industries strive for greener practices, innovative techniques such as bioplastics and energy-efficient processes gain traction, promising to reduce the environmental footprint of traditional manufacturing methods. Additionally, the integration of Industry 4.0 technologies, including IoT and AI, is revolutionizing the way manufacturers approach production, optimizing the injection molding process and improving product quality. With these emerging trends poised to redefine the field, understanding the top 10 trends in plastic injection molding for 2025 will equip manufacturers with the insights needed to stay competitive and drive innovation.

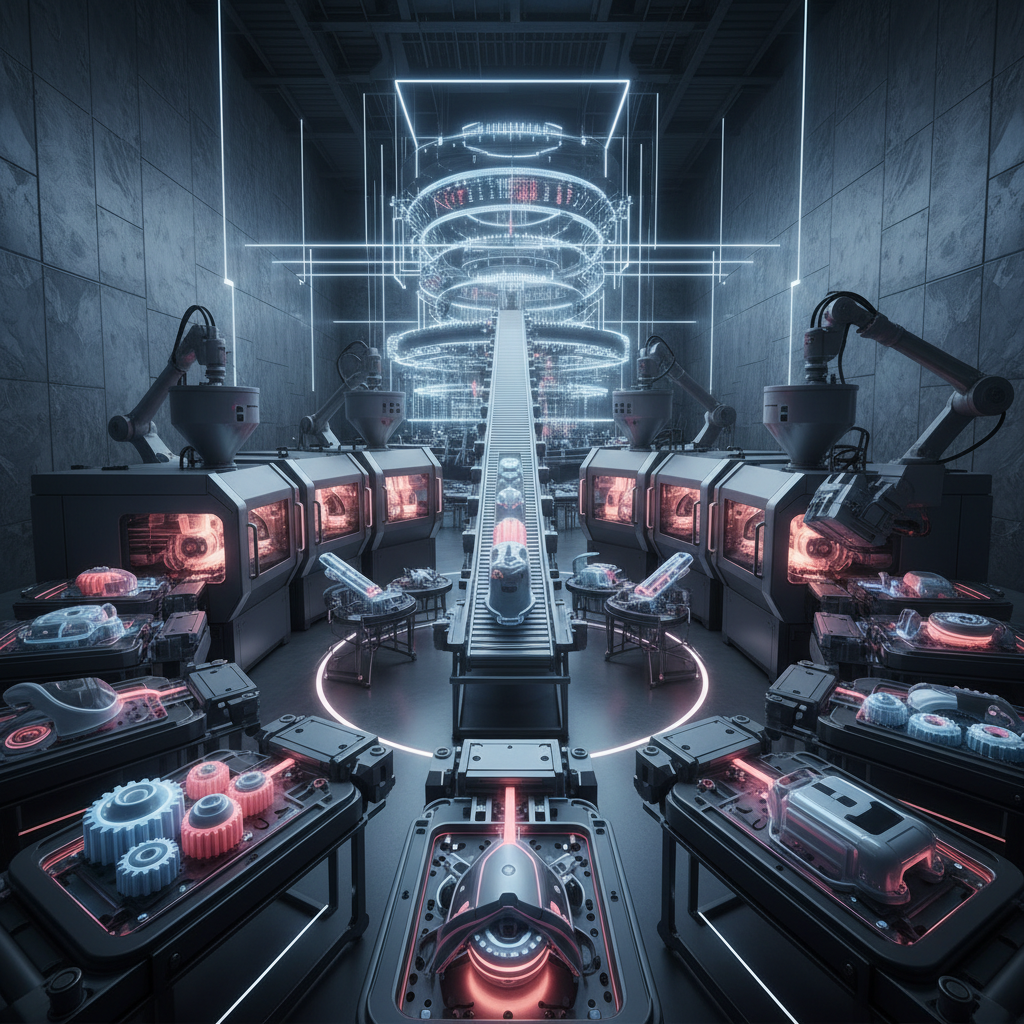

The landscape of plastic injection molding is undergoing a significant transformation, driven by the integration of artificial intelligence (AI) and automation. These emerging technologies are enhancing efficiency and precision within the manufacturing process. AI algorithms analyze vast amounts of data to optimize production schedules, reduce waste, and predict maintenance needs before issues arise. This proactive approach not only improves the overall output of injection molding systems but also minimizes downtime, ensuring that manufacturers remain competitive.

Automation is further revolutionizing the industry by streamlining workflows and improving consistency in production. Automated systems can carry out repetitive tasks with speed and accuracy, allowing human operators to focus on more complex decision-making roles. This shift not only enhances productivity but also elevates the quality of the final products. Together, AI and automation in plastic injection molding are setting the stage for a more innovative and efficient manufacturing environment, where rapid prototyping and customization can meet the evolving demands of various industries.

The shift towards sustainable practices in plastic injection molding is gaining significant momentum, particularly with the incorporation of biodegradable materials. As manufacturers strive to reduce their environmental footprint, biodegradable plastics are emerging as viable alternatives to traditional petroleum-based options. These innovative materials are often derived from renewable resources such as cornstarch, sugarcane, and other organic substances, allowing for the production of molds that break down naturally in the environment. This transformation not only addresses the critical issue of plastic waste but also aligns with the increasing consumer demand for eco-friendly products.

Furthermore, advancements in injection molding technology are enhancing the feasibility and efficiency of using biodegradable materials. New techniques and machinery designed for better material flow and heat management are essential for processing these alternative substrates. As manufacturers adapt their processes, they are not only improving product sustainability but also finding ways to maintain or even enhance performance qualities. This trend signifies a pivotal moment in the manufacturing sector, where innovation and responsibility are no longer mutually exclusive, paving the way for a more sustainable future in plastic injection molding.

The integration of 3D printing technology into the plastic injection molding process is paving the way for a new era of design and prototyping innovation. This combination allows for rapid iteration and the production of complex geometries that were previously unachievable with traditional methods. By utilizing 3D printing, manufacturers can create detailed prototypes at a fraction of the time and cost compared to conventional injection molding techniques. This not only accelerates the product development cycle but also enhances collaboration between design and engineering teams, as they can easily make adjustments based on real-time feedback.

Moreover, 3D printing enhances customization capabilities within the injection molding sector. With the ability to create bespoke molds tailored to specific project requirements, manufacturers can respond swiftly to market demands, offering personalized solutions without the hindrance of large initial investments. This shift towards an agile manufacturing approach not only optimizes resource utilization but also minimizes material waste, contributing to more sustainable production practices. As these technologies continue to evolve, the synergy between 3D printing and injection molding is set to redefine the parameters of manufacturing, fostering innovation and efficiency across the industry.

This bar chart illustrates the key trends that are expected to influence plastic injection molding by 2025. The advancements in integrating 3D printing technologies into the design and prototyping processes are highlighted as a significant factor driving innovation in this field.

The growing integration of data analytics in plastic injection molding is revolutionizing the manufacturing landscape, significantly enhancing quality control while minimizing waste. By harnessing real-time data collection and analysis, manufacturers can monitor production processes more closely, identifying deviations from optimal performance as they occur. This proactive approach allows for immediate adjustments, ensuring that products meet quality standards without compromising efficiency.

Additionally, data analytics plays a crucial role in forecasting and demand planning. Manufacturers can analyze historical data to predict future trends, allowing them to adjust production schedules and inventory levels accordingly. This not only reduces material waste associated with overproduction but also streamlines operations to better align with consumer demand. As these analytics tools become more sophisticated, we can expect further improvements in sustainability and profitability within the injection molding sector.

| Trend | Description | Impact on Quality Control | Waste Reduction Strategies |

|---|---|---|---|

| Advanced Data Analytics | Utilization of big data for predictive maintenance and process optimization. | Improved defect prediction and real-time quality monitoring. | Optimizing material usage based on data insights. |

| Automation and Robotics | Integration of robotic systems for handling and precision molding. | Enhanced precision reduces variability in product quality. | Minimization of material waste through precise handling. |

| Sustainable Materials | Usage of biodegradable and recycled materials in molding processes. | Reduction in environmental impact; greater consumer acceptance. | Decreased reliance on virgin plastics reduces waste generation. |

| Smart Manufacturing | Implementation of IoT for real-time monitoring and control. | Proactive quality adjustments based on live data feedback. | Reduction of scrap through continuous optimization techniques. |

| Artificial Intelligence | AI algorithms for process optimization and decision making. | Dynamic quality assessment and process correction. | Predictive models to minimize excess material use. |

| 3D Printing Integration | Combining injection molding with 3D printing for prototypes. | Faster iterations lead to improved product quality. | Reduction in material waste during prototyping phase. |

| Process Simulation Software | Virtual simulations to forecast injection molding outcomes. | Minimized risks of defects before actual production. | Optimized cycles reduce material overspending. |

| Customization and Flexibility | Ability to adapt molds for specialized requirements quickly. | Higher quality in personalized products tailored to market demands. | Reduced waste from unsold stock through customizable production. |

| Energy Efficiency | Implementation of energy-saving techniques in machinery. | Consistent operating conditions leading to better product quality. | Lower energy consumption translates to less waste and cost savings. |

| Regulatory Compliance | Adhering to changing regulations regarding materials and processes. | Ensured product safety and market acceptance. | Reducing failure rates due to compliance-related issues. |

The landscape of plastic injection molding is evolving rapidly, driven by the increasing demand for customization in manufacturing. As consumers seek unique products tailored to their preferences, manufacturers are turning to on-demand injection molding solutions. This trend allows companies to produce smaller batches of highly customized items, minimizing waste and reducing inventory costs while meeting the specific needs of customers.

On-demand injection molding enables rapid prototyping and flexible production capabilities, making it easier for businesses to respond to market changes swiftly. By leveraging advanced technologies such as 3D printing and digital manufacturing, manufacturers can create bespoke molds more efficiently. This not only shortens lead times but also enhances creativity in product design, further aligning with consumer desires for individuality and personalization. As this trend continues to grow, it is set to redefine the standards of efficiency and responsiveness within the plastic injection molding industry.

880 W 9th Street

Upland, California 91786

884 W 9th Street

Upland, California 91786

886 W 9th Street

Upland, California 91786

884 W 9th Street

Upland, California 91786