In recent years, the plastic injection molding industry in the USA has witnessed significant innovations, driven by advancements in technology and increasing demand for high-quality, efficient manufacturing processes. According to a report from MarketsandMarkets, the global plastic injection molding market is expected to reach approximately $346.06 billion by 2025, with North America being a key player in this growth, accounting for a substantial share of the market. The integration of smart manufacturing technologies, such as automation and real-time data analytics, has streamlined production lines and enhanced precision, further solidifying the position of plastic injection molding USA in the global supply chain. This ultimate guide delves into the latest innovations, techniques, and applications in plastic injection molding, providing valuable insights into how organizations can leverage these advancements to boost productivity and foster sustainable practices in their operations.

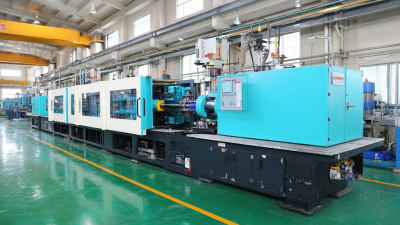

Plastic injection molding is a highly efficient manufacturing process widely used for producing a variety of plastic parts. During this procedure, molten plastic is injected into a mold where it cools and solidifies into the desired shape. As reported by the Plastics Industry Association, the injection molding segment accounted for approximately 32% of the overall plastics market in the United States, demonstrating its significance in the industry.

This versatile technique is favored for its ability to create complex geometries with high precision and repeatability. In fact, according to a study by Grand View Research, the global plastic injection molding market size was valued at approximately $321.78 billion in 2020 and is projected to expand at a CAGR of 5.5% from 2021 to 2028. These statistics underscore the demand for innovative designs and efficient production methods in the realm of plastic manufacturing. Moreover, advancements in technology, such as the use of robotics and automation, continue to enhance productivity and reduce waste, further solidifying injection molding as a key player in modern manufacturing processes.

The plastic injection molding industry in the USA is experiencing significant innovations that promise to enhance efficiency and sustainability. Key advancements include the rise of Liquid Injection Molding (LIM) and Liquid Silicone Rubber (LSR) technologies, which have carved out a noteworthy market share in recent years. The LIM and LSR injection machine market is poised for growth, with a projected value increase from approximately $148.41 million in 2023 to around $159.5 million by the end of 2024. This trend highlights the increasing demand for specialized machinery that supports the production of high-quality components, particularly in industries focusing on consumer electronics and automotive sectors.

Additionally, the plastic injection molding market is forecasted to witness a robust compound annual growth rate of 4.2%, expanding from $403.85 billion in 2024 to an estimated $561.58 billion by 2032. This growth trajectory indicates a shift towards more automated and energy-efficient injection molding processes, driven by advancements in machine types such as electric and hybrid systems. As industries prioritize sustainability and cost-efficiency, these technological innovations are essential for meeting modern manufacturing demands and ensuring long-term competitiveness in the global market.

Plastic injection molding is a cornerstone manufacturing process across various industries, including automotive, consumer goods, and medical devices. The method allows for the efficient and high-volume production of complex plastic parts, making it indispensable in sectors where precision and durability are essential. As industries evolve, the applications of plastic injection molding continue to expand, showing significant growth potential. For instance, the automotive industry increasingly utilizes lightweight components to enhance fuel efficiency without compromising safety, while the medical field relies on customized, sterile components that require stringent manufacturing processes.

The market for plastic injection molding is projected to experience remarkable growth, with the overall market expected to reach USD 382.53 billion by 2025 and escalate further to USD 580.44 billion by 2033. This growth is driven by advancements in technology, including automation and newer materials that enhance product quality and reduce production costs. Innovations in 3D injection molding are also gaining traction, providing manufacturers with the capability to produce intricate designs that were previously challenging to achieve. As these advancements continue, the adaptability of plastic injection molding in various industries will further solidify its role as a pivotal manufacturing process in the US and globally.

The environmental impact of plastic injection molding innovations in the USA is a critical topic as the industry advances. According to a 2021 study by the American Society of Plastics Engineers, approximately 30% of the materials used in injection molding are now derived from recycled sources. This shift significantly reduces the carbon footprint associated with plastic production, as recycling plastic can consume up to 88% less energy compared to producing new materials from virgin sources.

Furthermore, advancements in technology, such as the development of biodegradable plastics and energy-efficient machinery, are transforming the landscape of plastic injection molding. The U.S. Department of Energy reported that modern injection molding machines equipped with servo motors can reduce energy consumption by up to 50%. This energy efficiency not only lowers operational costs for manufacturers but also minimizes greenhouse gas emissions, contributing to a more sustainable manufacturing process. By embracing these innovations, the industry can play a pivotal role in addressing climate change while meeting the growing demand for plastic products.

The global plastic injection molding market is projected to grow significantly, with estimates suggesting an increase from $403.85 billion in 2024 to approximately $561.58 billion by 2032. This growth translates to a compound annual growth rate (CAGR) of 4.2%, indicating a robust demand driven by advancements in manufacturing technologies and materials. As industries continuously seek to enhance production efficiency and sustainability, the role of innovations in injection molding becomes even more critical.

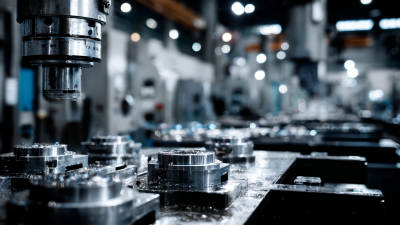

One of the key trends shaping the future of plastic injection molding is the rise of fully electric injection molding machines, which offer greater precision and energy efficiency compared to traditional hydraulic machines. The industry is witnessing a marked increase in the adoption of these machines, expected to enhance productivity and reduce environmental impact. Moreover, there is a growing emphasis on high-performance polymers, which are gaining popularity due to their superior properties such as durability and resistance to extreme conditions. This shift toward higher quality inputs is likely to drive further innovation within the industry, positioning it for a period of dynamic transformation.

| Innovation Area | Description | Future Trends | Impact |

|---|---|---|---|

| Sustainable Materials | Utilizing biodegradable and recycled materials in injection molding. | Increased use of bioplastics and innovations in material processing. | Reduces environmental impact and enhances product appeal. |

| Automation & Robotics | Integration of advanced robotics in the molding process for higher efficiency. | Adoption of IoT and AI for predictive maintenance and process optimization. | Improves precision and reduces labor costs. |

| Advanced Cooling Systems | Implementation of new cooling technologies to reduce cycle times. | Development of conformal cooling channels for more efficient heat dissipation. | Increases production efficiency and reduces energy consumption. |

| 3D Printing Integration | Combining injection molding with 3D printing for rapid prototyping and tooling. | Greater customization and faster turnaround for product development. | Enhances design flexibility and shortens lead times. |

| Smart Manufacturing | Leveraging data analytics and machine learning to optimize production. | Increased adoption of Industry 4.0 principles in manufacturing processes. | Enhances operational efficiency and product quality control. |

880 W 9th Street

Upland, California 91786

884 W 9th Street

Upland, California 91786

886 W 9th Street

Upland, California 91786

884 W 9th Street

Upland, California 91786